Digital printing of packaging has gained momentum over the past few years as new technologies and product offerings enter the market. In this document, we will examine three of the hottest packaging categories in the digital printing market: Labels, folding cartons, and corrugated packaging. Each packaging category comes with its requirements and challenges, so we will evaluate them individually. The same values that have made digital printing technology so relevant for document and signage production are equally important for all types of packaging. Quick turnarounds and short runs are major benefits, but the ability to segment, version, and personalize has become particularly important. The challenge lies not only in meeting the quality and substrate requirements but in understanding the needs of brand owners and other stakeholders in this rapidly accelerating market.

Key Findings

- Keypoint Intelligence – InfoTrends estimates that the global retail value of digitally printed labels, folding cartons, and corrugated packaging will exceed $14 billion by 2022.

- With over 20 years of history, colour digital printing of labels is the largest and longest-running of the digital print categories within the packaging.

- Folding carton producers are called “converters” because they convert media into folding cartons for use by product manufacturers.

- Multi-pass inkjet devices—where a CMYK head moves back and forth across a big corrugated sheet—are very common in corrugated converting because they print test versions easily and well.

Recommendations

1. Substrates rule! The substrate selection used for packaging is one aspect that differentiates labels, folding cartons, and corrugated packaging from other types of printed material—particularly the paper documents that digital print systems have been most successful at producing.

- This means that familiarity with pressure-sensitive media, thick board stocks, and corrugated is a key component of addressing this market.

- Small formats for labels and large formats for folding cartons and corrugated packages are also emblematic of the market’s nature.

2. Make sure you have the right expertise. Special skill sets are required for any commercial printer that is interested in entering the packaging market. Be sure that employee capabilities and training programs are in place to support any purchases of systems and software for the digital printing of packaging.

3. Target neighbouring applications and existing customers. There are some areas where packaging and marketing overlap, and where short runs and personalization are a great fit. These include table toppers, promotional displays, customized labels, and gift packaging.

4. Brand colour accuracy matters. Brand owners care about colour accuracy as much (if not more) as marketing managers. As a result, it is critical that your colour matching, proofing, and colour consistency capabilities are top-notch.

5. Build the workflow to manage large numbers of SKUs. Job tracking becomes particularly important in a packaging environment as you work with brand owners who may have tens of thousands of SKUs. Managing those variations requires an extremely solid workflow.

What Is Driving the Packaging Market to Digital Print?

Three factors are combining to make digital printing essential to the packaging market:

- The need for short runs: Brands worldwide are increasingly ordering print more often and in smaller amounts, making short-run printing more of a requirement.

- Market acceptance: Packaging converters are adopting the technology and are developing the programs as well as skill sets necessary to promote and sell digital printing.

- Improved technology: Digital printing system vendors are leveraging technological advancements to develop new and innovative products.

Although the underlying benefits may vary somewhat by type of packaging (e.g., labels, folding cartons, and corrugated), there are some critical advantages that digital print offers to all packaging applications:

- Prototypes, test runs, and on-demand production: The need for short runs includes a few key categories. During the packaging design phase, prototypes and test runs are needed to ensure that the package meets the needs of the brand owner. Once the design phase is completed, it is common to produce packaging on-demand as the market requires it. This may include localized, customized, or personalized packaging.

- Localization, customization, and personalization: Brand owners value digital print’s ability to produce variable data, which enables them to localize packaging for regional markets, customize packaging for events or holidays, or even personalize a product to an individual. This concept of “mass customization” is taking hold as a basic strategy for many brand owners.

- Operational efficiency: Operational efficiency is equally important for brand owners and packaging converters. For brand owners, the increasing number of stock-keeping units (SKUs) drives the need for supply chain efficiency and responsiveness to unexpected changes. For packaging converters, digital print’s efficiency in printing short runs also makes their analogue presses more efficient by taking short runs away from them and enabling these devices to print just the long runs where analogue excels.

Important Definitions for the Packaging Market

Two definitions are important in understanding the packaging market: Primary and secondary packaging. Primary packaging is the first level of packaging that the product is housed in (e.g., a bottle of wine with its label or a folding carton box for facial tissues). Secondary packaging is one step away from the product (e.g., the cardboard box containing a 6-pack of beer or a corrugated carton holding multiple cans of produce.

The Growth of Digital Print in the Packaging Market

Keypoint Intelligence – InfoTrends (InfoTrends) estimates that the global retail value of digitally printed labels, folding cartons, and corrugated packaging will exceed $14 billion by 2022. The largest segment within the digital printing of packaging market is label printing, which accounted for more than $4.5 billion in global retail value of print in 2017 and is expected to demonstrate a compound annual growth rate (CAGR) of 14% between now and 2022. Corrugated is the next largest segment, having produced nearly $1 billion in 2017 and expected to reach nearly $5 billion in 2022 (39% CAGR). Digital printing of folding cartons will achieve a 20% CAGR, clearing $1 billion by 2022.

Table 1: Global Retail Value of Labels, Folding Cartons, and Corrugated ($Millions)

Digital Printing of Labels

InfoTrends defines a production-level label digital printing system as a digital printer with the following characteristics:

- Capable of producing at least process colour (CMYK) output

- Designed to print labels

- Rugged enough to operate three shifts per day, seven days a week

- An average monthly print volume of at least 1 million labels

Printers that meet these requirements produce colour labels of all types, including shrink sleeves, and may also print other applications like tickets or tags.

From a technology perspective, all the production digital colour label printers print on roll media, generally in widths from 200 to 350 millimetres (one very common width is 330 millimetres/13 inches), although some systems are as wide as 700 millimetres (approximately 27 inches). Though useful, cut-sheet devices that print on pre-die-cut label stock are generally not primarily focused on high-colour graphic label production and are therefore not considered part of this segment. In the same way, the class of tabletop colour label printers, while interesting and useful for very small runs, is not part of this InfoTrends forecast segment.

Colour digital label printers mainly print primary labels for products such as foods, beverages, health & beauty products, and drugs. When primary labels are produced, they are generally printed on paper and film stocks (coated or uncoated). Although pressure-sensitive label stock will be used for most applications, other label stocks that may be used include shrink sleeve, in-mould, and heat transfer media. Some digital systems also produce other types of colour labels (e.g., industrial labels, shelf labels, logistics labels).

With over 20 years of history, colour digital printing of labels is the largest and longest-running of the digital print categories within the packaging. Electrophotographic (toner-based) roll-fed printers first entered the market in 1996 and still produce most of today’s digitally printed labels. At the same time, however, inkjet printers using ultraviolet (UV) or aqueous inks have been in the market for about 10 years and play a growing role in the label converting industry.

Digital Printing of Folding Cartons

InfoTrends defines digital colour folding carton printing systems as digital printers that are capable of the following:

- Producing process colour (CMYK) folding carton output on single-ply paperboard media

- Operating continuously in a production facility (3 shifts/seven days a week)

- Outputting an average monthly print volume of at least 1 million cartons per month

Digital printing for folding cartons typically entails primary packaging for a wide range of consumer goods like foods, drinks, cosmetics, drugs, health & beauty products, consumer electronics, and software. These folding cartons are generally made of single-ply paperboard, a wood-fibre based media that can be coated or uncoated in thicknesses ranging from 14 to 24 points (350 to 600 microns). Plastic media is also used on occasion. Some printers produce other applications at least occasionally, including blister cards, direct mail cards, and other commercial print jobs.

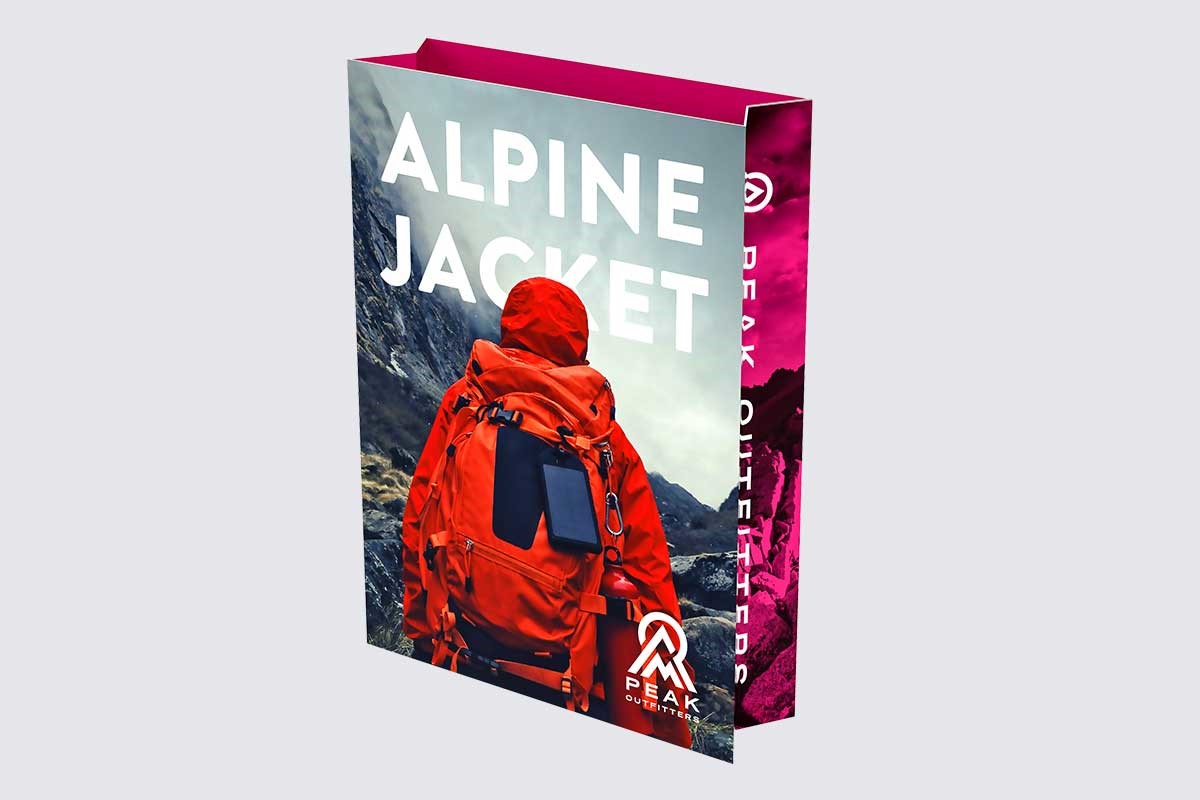

Folding carton producers are called “converters” because they convert media into folding cartons for use by product manufacturers. Some also make other packaging applications in addition to folding cartons. Nearly all folding carton converters use analogue printing presses on large sheets of media (e.g., B1-format sheets are 1,000 by 707 millimetres or 27.8 by 39.4 inches). Large sheet sizes have been a bit of a barrier for digital printing, but B2-format and larger digital printing systems have gradually been entering the market. Folding carton converters are also generally involved in enhancement processes like foiling, varnishing, and laminating, as well as finishing processes like cutting, folding, and glueing.

Some applications lie adjacent to the traditional folding carton market and have a distinct marketing or promotional flavour. These applications use board stocks, but may only be needed in smaller quantities or for jobs that benefit from personalization. Examples include gift packaging for promotional items, packages for small businesses or crafters, and tabletop displays for retail/restaurant settings. Some of these items can even be produced using pre-converted, die-cut substrates. This border area between traditional folding-carton packaging and marketing/promotional initiatives can be a good way to enter the folding carton market. One advantage of these applications is that they may fit on smaller sheet sizes and remain within the substrate range supported by existing products that are used for document applications.

Digital Printing of Corrugated

InfoTrends defines corrugated digital printing systems as printers that:

- Can produce process colour (CMYK) output

- Exclusively or mainly print corrugated packaging

- Can operate around the clock seven days a week

Digital printers that print corrugated on a part-time or occasional basis are not counted in InfoTrends’ forecasts. Furthermore, although other technologies could conceivably be used, these digital printing systems are exclusively using inkjet at this time. Targeted application segments include cartons and secondary packaging as well as retail displays and some primary packaging.

There are two types of corrugated printing:

- Pre-printing: This involves printing a layer of liner paper before using it in a corrugator to then make a fully printed corrugated board. This method is relatively rare in today’s digital printing world; only one vendor offers such a pre-print digital system at this time.

- Post-printing: Involves printing directly on a corrugated board that has already been fully formed in a corrugator. Post-printing is the most common approach in digital printing.

Inkjet print for corrugated packaging has been around for decades, although mostly for the printing of prototypes on wide format “multi-pass” flatbed printers rather than full-scale production on big “single-pass” print systems. Multi-pass inkjet devices—where a CMYK head moves back and forth across a big corrugated sheet—are very common in corrugated converting because they print test versions easily and well. Increases in speed and format for inkjet printing systems have expanded the role of inkjet beyond prototyping to include production runs as well as the creation of retail displays that are made from corrugated boards. Even some automated multi-pass flatbed printers print short production runs. Meanwhile, bigger and costlier single-pass systems—those that print a wide bed with full colour in one pass—are making inkjet a growing source of short and long-run printing of corrugated. Corrugated converters are discovering that digital printing systems provide a useful alternative to the flexographic and lithographic presses that still account for nearly all high-graphics printing in this market.

Growth in the use of digital print for corrugated packages fits in well with the needs of brand owners who are finding that the big packaging surfaces on corrugated packages are strategic media for promoting their brand imagery. The trend toward shelf-ready packaging and retail store displays, which commonly use corrugated boards, is another reason for the growth in digital printing.

InfoTrends’ Opinion

Digital print’s capabilities—prototyping and proofing quickly and efficiently, fulfilling on-demand as customers require, and customizing/personalizing—all dovetail very nicely with the needs of today’s market. Adding digital print to an analogue shop to meet those needs, and to print short production runs, increases converting efficiency by enabling short runs and freeing analogue presses for the longer runs that they are better suited for. On top of that, the digital print represents just a small fraction of today’s overall packaging market, so it is very well-positioned for growth.

Explore Ricoh Pro C7200X Graphics Art Edition Digital Production Press