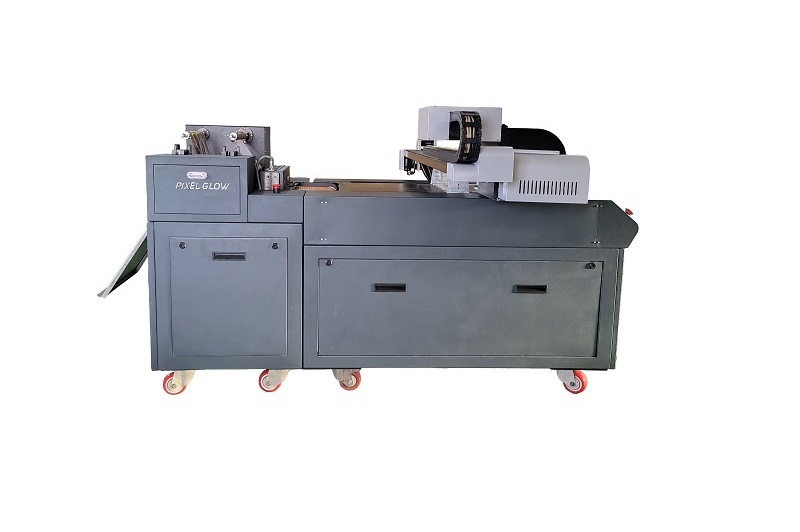

Scodix Ultra 2500 SHD

Designed for: Commercial and Specialty Printing, Packaging, W2P, Publishing

- Quality and Productivity

- Quality and Productivity

- B2 Format

- Certified Sustainable

Specifications

Technical Specifications

| Feature | Description |

|---|---|

| Scodix SHD

Scodix MLE Scodix PAS Scodix VDE Scodix RSP Scodix ART |

Precision quality and fine lines

Supports up to 7 layers of Scodix polymer build for Scodix Sculpture Secure polymer curing in 3 stage process Variable Data Embellishment Automated perfect registration Supports anti static, transparent and reflective media |

| Resolution | Up to 2,540 x 450 DPI |

| Scodix RSP™ Technology | 4-CCD camera system, RSP™ (Rotate, Scale, Position) algorithm, automatic positioning, ±100 micron image to image registration |

| Automatic Registration Calibration | New wide format and fully automatic- No operator intervention |

| Throughput (Max) | 1446 SPH |

| Substrate Format (Min: Max-L x W) | 297 x 420 mm: 760 x 1,060 mm/11.7 x 16.5 in: 30 x 41.7 in |

| Printing Area (Max L x W) | 504 x 748 mm/19.8 x 29.4 in |

| Polymer | Variety of Scodix Polymers according to applications choice |

| Polymer Layer Thickness | From 5 up to 400 microns (MLE 7 layers) |

| Polymer Switch | Automatic |

| Variable Data Enhancement (VDE) | PDF, optimized PDF, barcode system (optional), tiff |

| Foil Roll Width (Min-Max) | 50-550 mm/1.97-21.65 in |

| Foil Roll Size (Max) | Diameter: 30 cm/11.8 in; Length: 2,000 m / 2187 yd, Core: 77 mm/3 in |

| Number of Simultaneous Rolls | Up to 4-rolls |

| Substrates* | Offset, Coated/Uncoated, PVC, Laminated, Transparent, Metallic |

| Substrate Range | 135-675 gsm/6-30 points, up to 2 mm |

| Compatibility | Offset, HP Indigo ElectroInk, Inkjet, Lamination, Toner, Xerox, Ricoh, Canon |

| Feeder/Stacker | Industrial** |

| Scodix Software | Scodix Studio Station |

*See Scodix Recommended Substrate List (RML) for foil where surface tension is within 36-44 dyne/cm

**Scodix Ultra 2500 Pro includes Pallet Feeder Stacker

Scodix AI

It gives unsavvy designers the choice to add embellishment and provides print providers with added revenue sources without adding pre-press costs.

Scodix AI analyzes designs and processes embellishment suggestions for Scodix Sense and Scodix Foil.

Scodix AI is compatible with any web interface and integrates seamlessly into Web-to-Print and online storefronts.

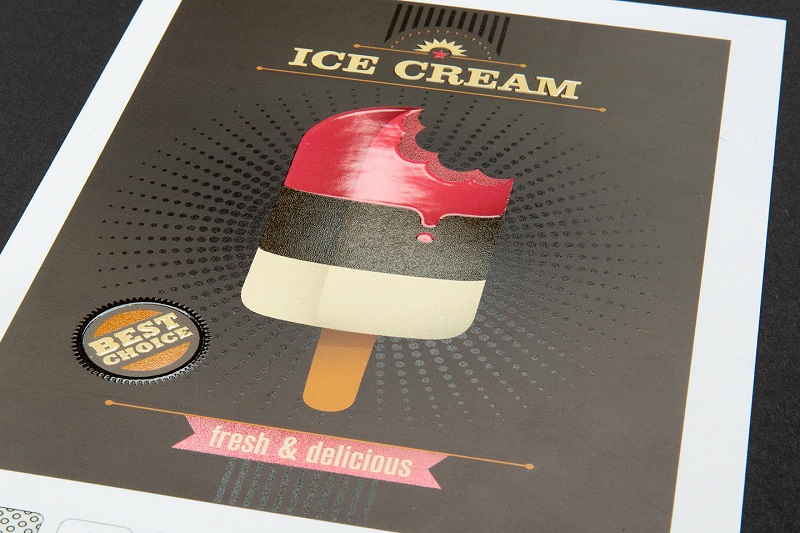

Scodix Applications

Scodix offers an unprecedented selection of 16 different applications, which work seamlessly on a single Scodix digital enhancement press.

With 16 different Scodix applications, Print Service Providers (PSPs) can deliver highly differentiated premium products, in-house – without the costs of traditional embellishments. Every Scodix application has become a powerful, high-quality and cost-effective replacement for the traditional analog machine.

Never before seen designs can now be easily produced using different combinations of applications, such as Scodix Sense™ on Scodix Foil™, Scodix Foil™ on foil and many other variations. Each of the 16 Scodix applications and additional combinations of Scodix applications provide PSPs with the unique ability to print any of them on a single press!

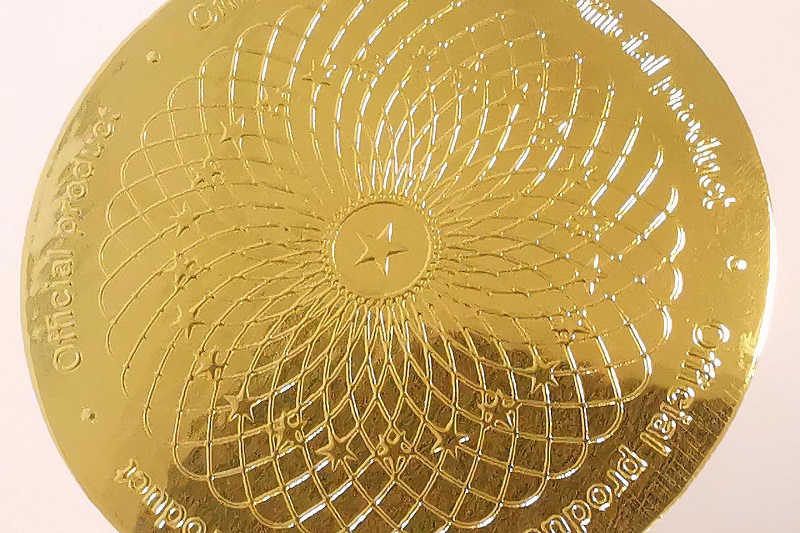

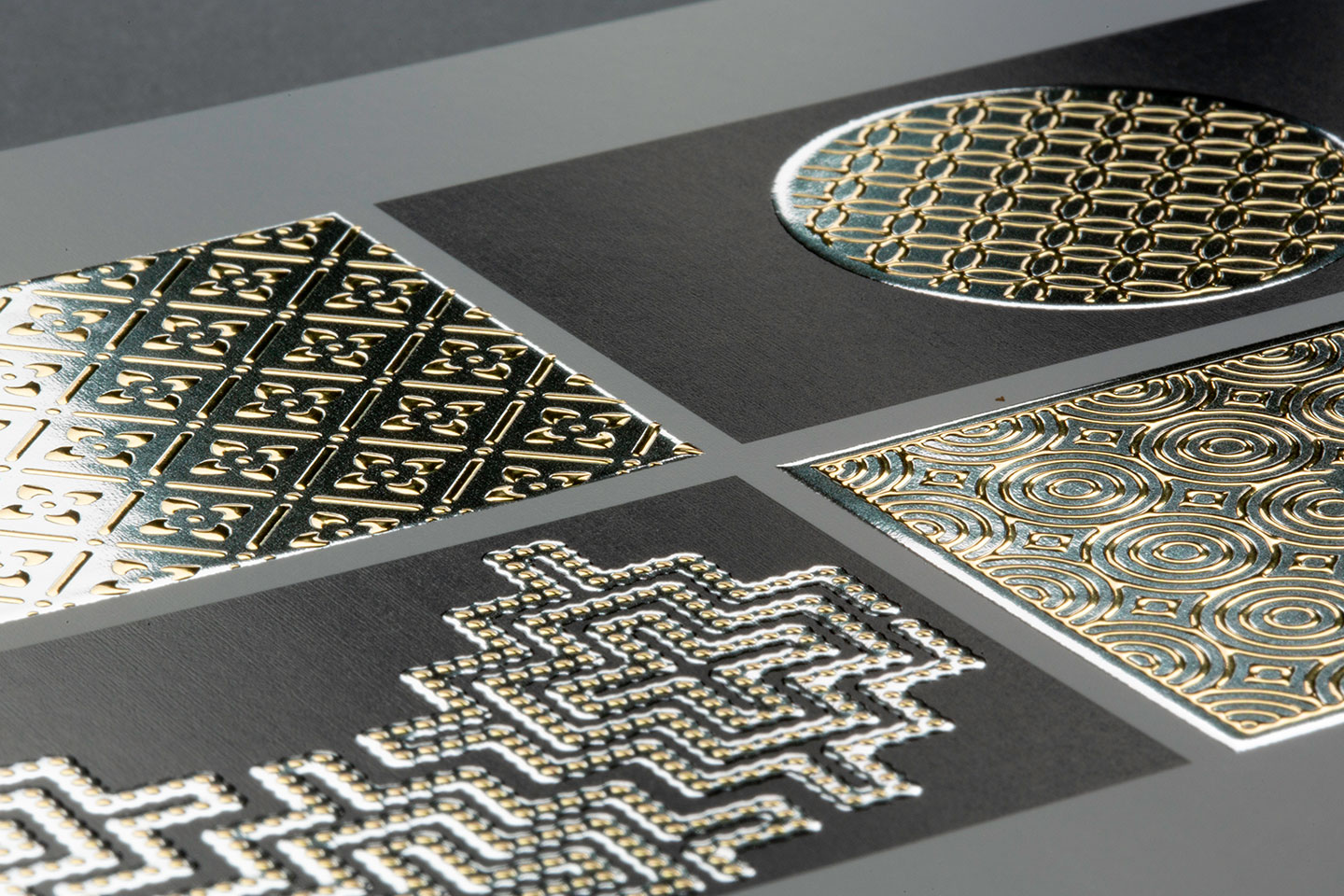

Scodix SHD™

Give brands the freedom to embellish any design defined by fine lines, intricate details and patterns, tiny text and large surface flat foiling. Finally, all is possible with Scodix Smart High-Definition.

Scodix Uncoated™

Adding exquisite embellishment designs onto affordable uncoated paper elevates the visual impact and allure of sustainable packaging and printed media.

Scodix Transparent™

Infuse creativity with Scodix Art to the packaging trend of clear product windows for items like toys and confectionery, enhancing their visibility and appeal

Scodix Matte™

Emulate the effect of blind embossing with the freedom to create intricate designs and detailing without incurring the expenses associated with costly dies

Scodix Reflective™

Metallic, rainbow, and holographic media achieve an elevated level of luxury and appeal when enhanced with Scodix embellishments.

Scodix Security™

Embrace Scodix technology to safeguard luxury and limited editions of collectible and high-end products by blending embellishments as layers, utilizing permutations of Scodix Sense, customized C&C foils, VDE serialization, and fine-detail chevrons to create one-of-a-kind anti-counterfeit elements.

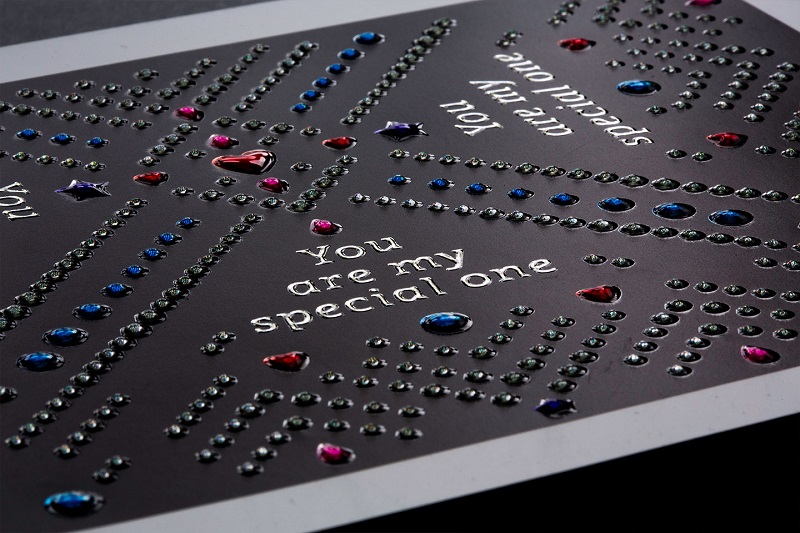

Scodix Sculpture™

Unleash creativity with the ability to sculpt layer upon layer of Scodix Sense™, adding value to printed products. Feel the difference of enhanced 3D tactililty on print.

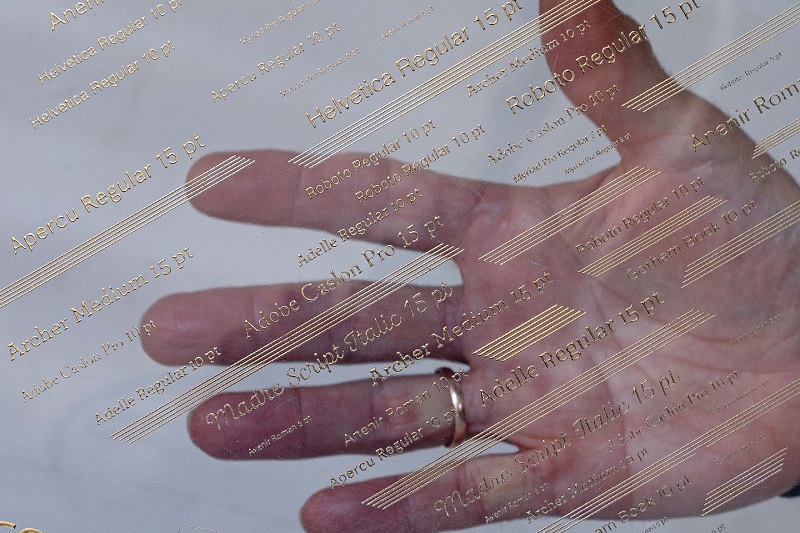

Scodix Sense™

Achieve the effect of raised glossy embossing/textures, enabling PSPs, folding carton converters, designers and brand owners to transform ordinary products and applications into extraordinary creations.

Scodix Foil™

Print real foil, cost-effectively, without the need for dies and molds for short to medium runs; includes option to use variable data and personalize products using real foil to achieve unmatched foil enhancement results.

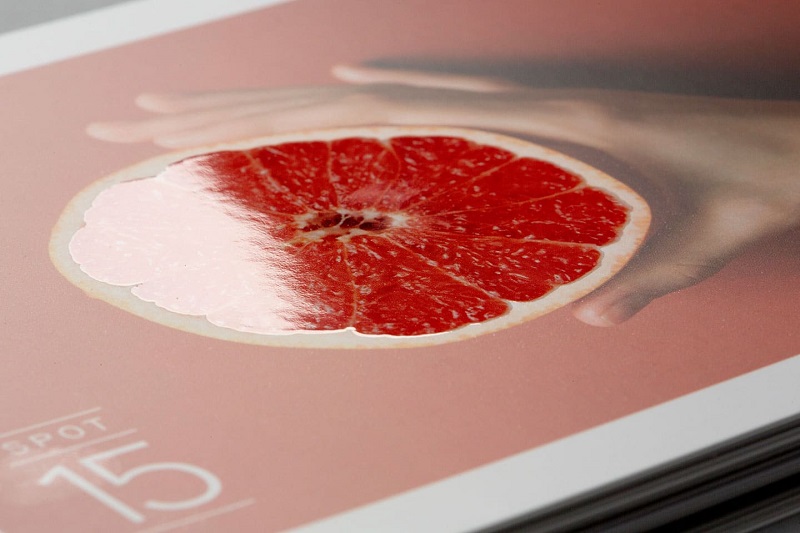

Scodix Spot™

Print selective spot varnish for short to medium runs, digitally recreating the effect of traditional analog flat varnishes, but without the set-up time or mess.

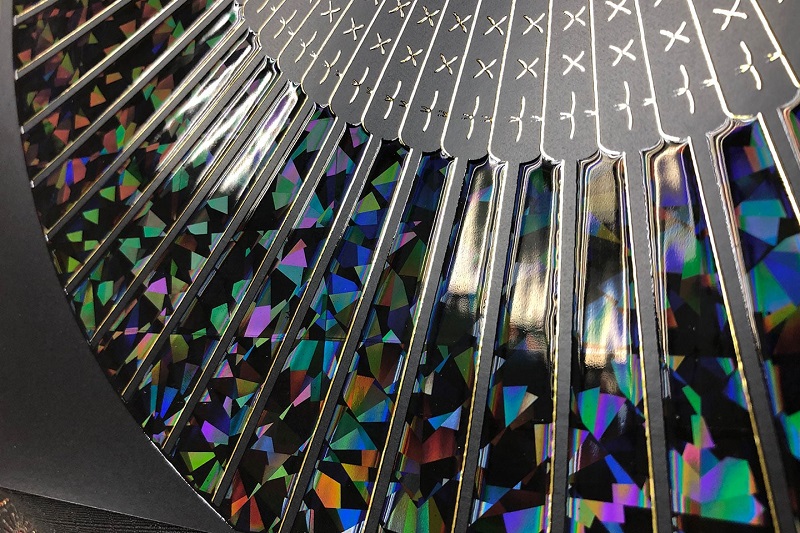

Scodix Cast&Cure™

Unique capability based on the Scodix Foil™ station design, creating high-impact, 3D-holographic dramatic effects.

Scodix Glitter™

The usage of Scodix Foil with the texture of glitter and the combination of Scodix Sense™ with a pattern of glitter, enables users to get the look and the feel of real glitter without any mess all in a digital process.

Scodix VDE™

Accentuate the impact of digital enhancement with personalized, customized text and graphics using Scodix Sense™, variable data and Scodix Foil™, real foil, Scodix Cast&Cure™ and more, to achieve unmatched personalization enhancement results.

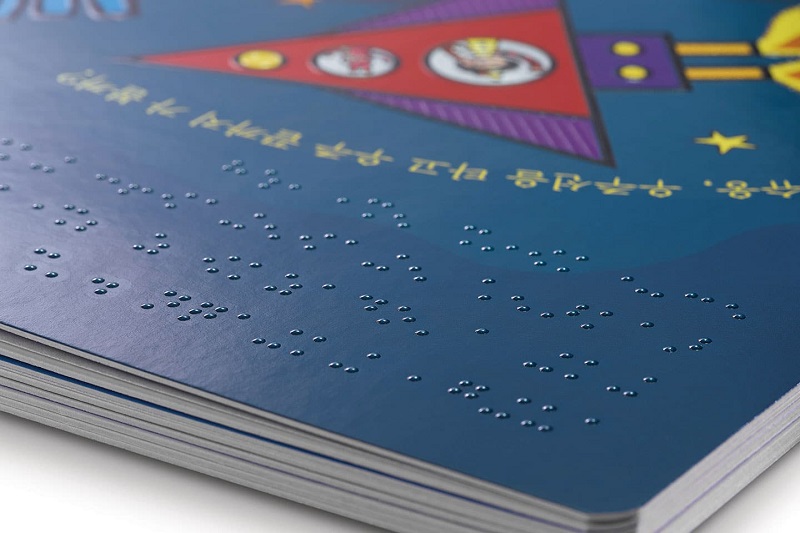

Scodix Braille™

Designed to provide a better quality of life for the blind and visually impaired around the world using this ultra innovative solution.

Scodix Crystal™

Add colorful sparkle effects with Scodix Crystal™ and create real 3D items with a high-build polymer; replacing the manual positioning of crystals on products such as greeting cards and brochures.

Scodix Technology

6 Technologies for Ultimate Performance

Scodix is dedicated to optimizing quality and productivity both on the production floor and in the production workflow. Six technologies drive the Scodix Ultra presses to achieve maximum output and high-quality print functionality.

Scodix SHD

Scodix Smart High-Definition (SHD) controls the precise placement and drop size of Scodix polymer to surface areas. The algorithms enable precision sharp borders for the finest details designs.

Scodix MLE

Scodix Multi Layer Embellishment (MLE) is the structured layering of the polymer by repeating rotations of the media under the print heads in a single pass. Multiple cycling of the paper path achieves high-efficiency building of tactilie layers, for Scodix Sculturing, Scodix Braille and Scodix Crystal applications.

Scodix AI

Scodix AI through insights gained from databases of embellishment files, identifies the best elements in a CMYK design suited for embellishment layering. From within a web interface, a choice of options is automated. Scodix AI offers print providers the ability to automatically value-up print jobs at the click of a button.

Scodix VDE

Scodix VDE allows for the customization of print enhancements on a variable data basis. With Scodix VDE, users can apply enhancements such as spot UV, foil, embossing, and more to individual elements within a printed piece, making each one stand out and grab the recipient’s attention.

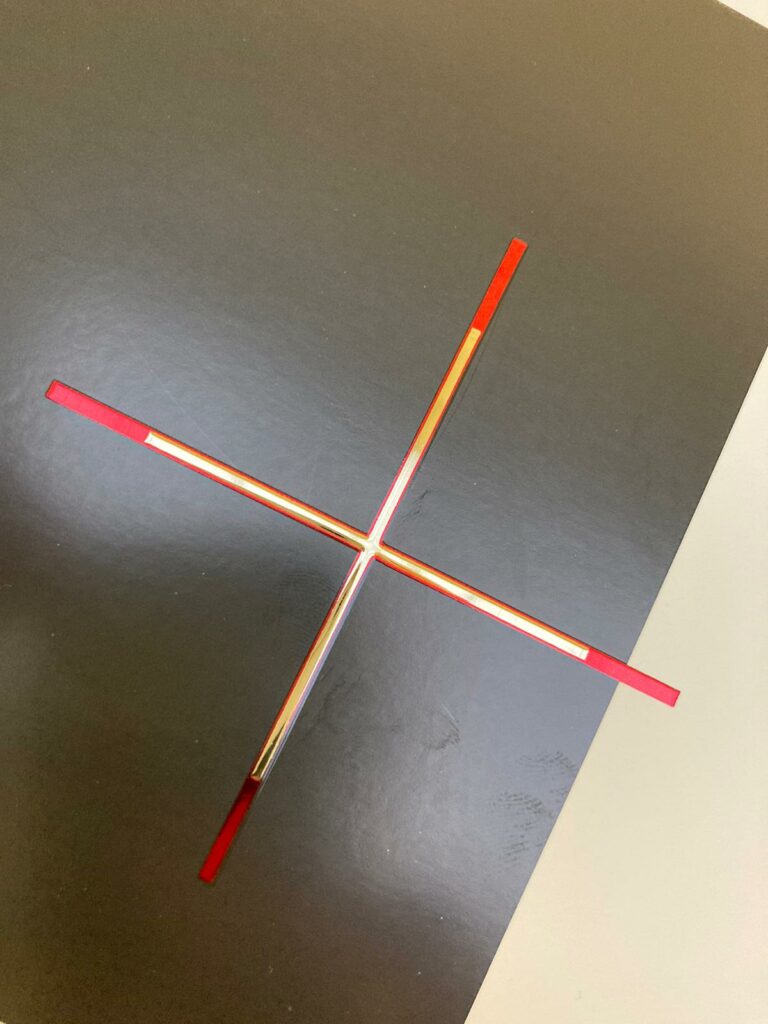

Scodix PAS™

Scodix Pinning Activate and Secure sets the polymer droplets in place on the individual sheets before continuing on the paper path to receive foil and final curing before delivery.

Scodix RSP™

Scodix Rotate-Scale-Position (RSP) positions the Scodix embellishment to the image with pinpoint accuracy by scanning each individual print sheet before delivering the Scodix polymer liquids designated embellishment areas.

basysPrint

basysPrint Cron

Cron Kodak

Kodak ECRM

ECRM HuQ

HuQ Heights

Heights G&J

G&J Digicut

Digicut ITOTEC

ITOTEC Labelmen

Labelmen RICOH

RICOH Color Logic

Color Logic Scodix

Scodix .

. akk

akk intaGlios

intaGlios Canon

Canon Contex

Contex i2s

i2s