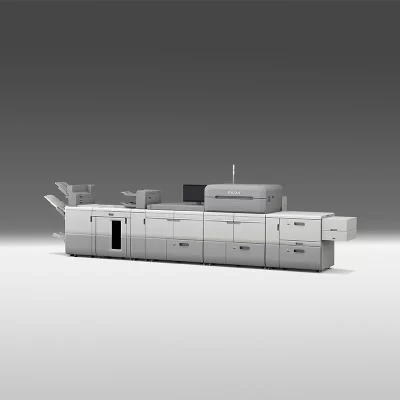

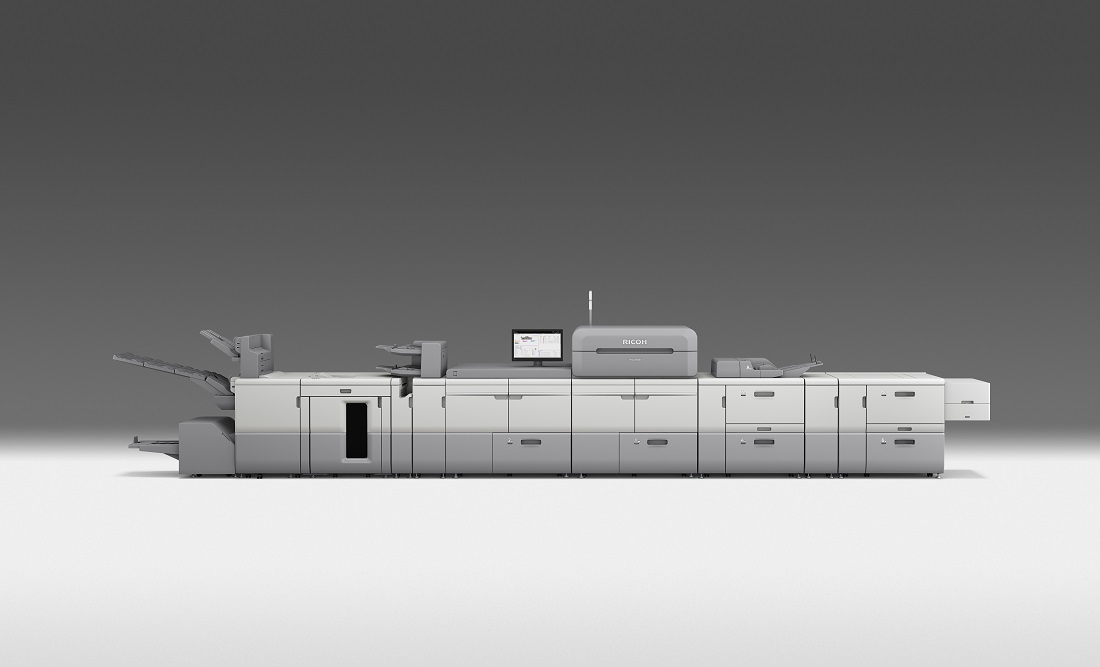

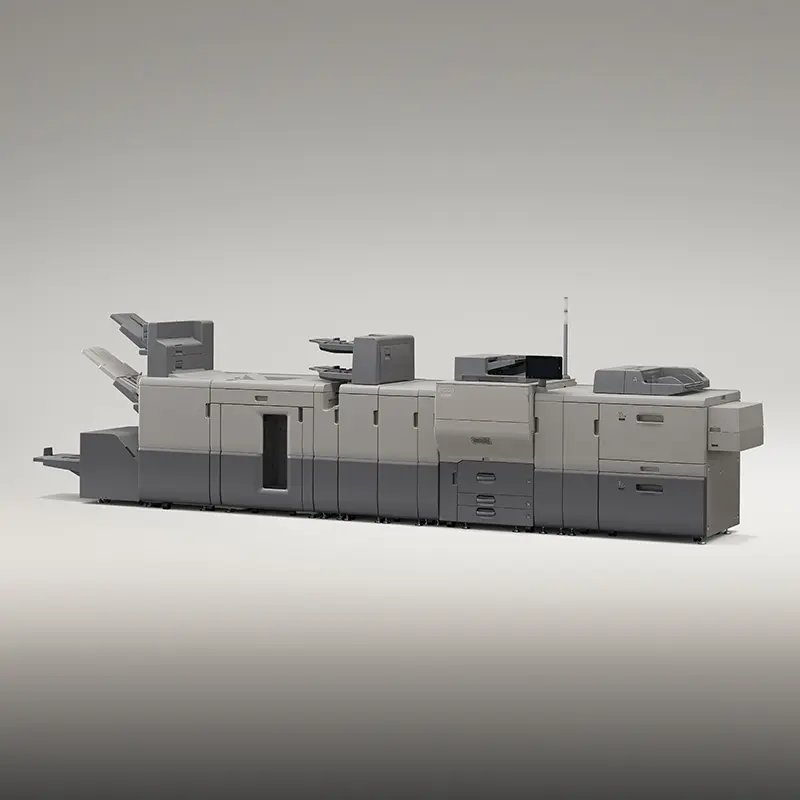

RICOH Pro C9500

Colour production printer

- Upgradeable to 135 ppm

- 40–470 g/m2

- 18,100-sheet max input

- RICOH GC OS controller

Overview

Pursue your next stage of growth

Scalable and affordable, the RICOH Pro C9500 Color Sheet-Fed Printer is a top-of-the-line system built for today’s realities to prepare you for what’s next. Get the performance capabilities you need – reliably produce one million impressions per month; achieve exceptional color with precise matching and accurate front-to-back registration; pivot from offset to digital without compromise to take on high-margin variable jobs and light packaging. Come through every time for clients in need of shorter runs with tight deadlines.

Approach new markets with more to offer

Greater media flexibility and support for thick or thin paper as well as synthetic and specialty substrates allow you to produce more applications, in more configurations. Embrace new creative possibilities whether the job is a direct mail, catalog or photo book. Produce custom covers and POP with media support up to 173 lb. cover (470 gsm). Add the option to go oversized up to 49.6″ to say yes to multi-panel brochures, light signage, book wraps and more.

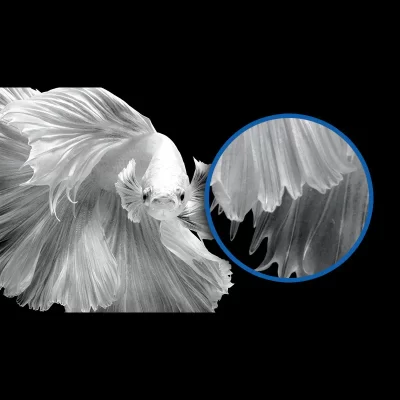

Vivid detail in every print

Better serve retail, hospitality, finance and other high-end markets where color quality and accuracy are essential. Produce photo-quality images with 2400 × 4800 dpi resolution. Groundbreaking technologies such as Auto Color Diagnosis and Image Quality Monitor automatically detect imperfections and instantly adjust to maintain consistency. Precise front-to-back registration empowers you to produce high-value, duplexed jobs with total confidence.

Engineered to outperform

Efficiency. Capacity. Power. Control. The RICOH Pro C9500 gets it done with blazing speeds up to 135 ppm*, monthly volumes of up to one million pages, a powerful Fiery® controller and a robust paper capacity of 18,100 sheets. A new, full-view 21″ color touchscreen operation panel simplifies the user experience and features a customizable display for faster job execution.

More finishing options to meet more customer needs

Enjoy end-to-end production capabilities with automated inline finishing. Produce professional saddle-stitched booklets, ring-bound books, and folded direct mail easily, efficiently and affordably. Keep more jobs in-house and spark business growth. Work smarter, not harder.

Applications

Turn media flexibility into business opportunity

Grow your application capabilities with support for thin and thick paper, as well as synthetic and specialty substrates. With media support up to 470 gsm, you can expand into new industries and create profitable revenue streams by delivering applications that other digital systems can’t. Take on more work, including high-margin short-run packaging, counter cards, catalogs, books, small signage and more.

Go big with oversized applications for more impact

Produce dazzling work that breaks through the clutter and gets seen. The RICOH Pro C9500 is engineered to handle more media sizes, including oversized sheets up to 49.6″. Give print buyers more real estate to tell their story and your business the benefit of maximizing media. Produce double-sided applications, light packaging and full-sized tri-fold brochures on a single digital system. Oversized banner sheet printing has been increased up to 38″.

Create more targeted, more relevant work

Embrace digital to produce attention-grabbing materials with versioning and deep personalization. Enhance direct mail, coupons, catalogs and collateral materials with customized offers that deliver real results. With the new Fiery® N-70 Controller, your operators will process complex files faster and easier than ever. Reduce waste. Enter high-margin segments. Bring greater value to every job.

Register more media for repeatable results

The RICOH Pro C9500 media management tool makes it easy for operators of all levels to achieve predictable results. Simply set the optimal conditions for feeding, transfer and fusing temperature to reduce errors and drive efficiency. Customize, organize and access media library selections directly from the Smart Operation Panel. Better workflow operations and less waste mean greater profitability.

Services to help you maximize your investment

Work alongside Ricoh’s experts to realize the full potential of your RICOH Pro C9500. Gain the support of an exceptional and knowledgeable professional services team who bring deep, real-world experience to every engagement. From operator training and finishing solutions to business development and G7 certification, we are your single-source partner.

Quality

Enter new markets where dynamic color and pristine pages are essential

Quality is often the one metric by which printers are measured, and with the RICOH Pro C9500 by your side, you will have a genuine competitive edge. It features VCSEL technology which emits 40 laser beams simultaneously, resulting in 2400 × 4800 dpi image resolution. Achieve crisp text, fine lines, smooth gradations and realistic image reproduction with game-changing Active Toner Density Control.

Make the first page as vivid as the last

Approach markets where color accuracy is key. Quality and fluctuation controls maintain image integrity and keep work flowing. Inline sensors deliver precise calibration while automated technologies continually monitor the system to reduce the chance of toner unevenness and ensure color stability on every page. Deliver predictable results that maximize profitability thanks to world-first technologies that take operator subjectivity out of the equation.

Gloss or matte? You decide.

On the RICOH Pro C9500, operators of all levels can deliver high-end, offset like quality and meet customer demands. Accelerating your digital migration strategy is an exciting new feature exclusive to Ricoh — Gloss Control Mode. Stand out in a crowded market with the option to offer customers a gloss finish or a matte effect. Achieve a greater range of desired outcomes based on media, artwork and preference.

Maintain color stability with automated technologies

Reduce waste and watch productivity soar with a digital press that empowers a new generation of operators to succeed regardless of skill level. Auto Color Diagnosis (ACD) automatically scans images during printing and adjusts color values that deviate from ripped image data. Image Quality Monitor (IQM) is a defect image monitor that alerts operators of streaks or spots on printed media, allowing them to be removed before they are passed on to finishing.

Precise registration gets even more accurate

Confidently go after upscale direct mail, business cards, catalogs, brochures and booklet work where page registration is a must. The RICOH Pro C9500 features internal sensors that scan registration marks and automatically adjust the image area to correct for any shift in media shrinkage caused by fusing heat when duplexing. Benefit from Ricoh technologies and increase profit margins on high-value, duplexed jobs with smaller runs and quick turns.

Leverage our color expertise and go further

Our experts are ready to get hands-on and help you implement a color management strategy built around your unique operation, skillset and workflow. Work one-on-one with Ricoh professionals to achieve the highest level of color quality and accuracy — for every client, on every job, every time.

Specification

| Functions | |

| Colour | Yes |

| Printer controller – standard | RICOH GC OS |

| Printer controller – optional | Color Controller N-50 Color Controller N-70 |

| Operation panel | 21.5″ Full HD touchscreen |

| Physical dimensions (WxDxH)—mainframe | 2,520 x 990 x 1,500 mm |

| Physical dimensions (WxDxH)—other | 2,520 x 990 x 1,870 mm—mainframe with Attention Light 1,054 x 730 x 1,000 mm—Vacuum-Feed LCIT RT5150 1,290 x 730 x 1,000 mm—Vacuum-Feed LCIT RT5150 with Vacuum-Feed Banner Sheet Tray Type S9 attached 1,519 x 730 x 1,000 mm—Vacuum-Feed LCIT RT5150 with Extension Vacuum-Feed Banner Sheet Tray Type S14 attached 330 x 730 x 1,000 mm—Bridge Unit BU5010 690 x 561 x 210 mm—Multi-Bypass Tray BY5020 1,290 x 730 x 1,000 mm—Vacuum-Feed Banner Sheet Tray Type S9 1,290 x 730 x 1,302 mm—Vacuum-Feed Banner Sheet Tray Type S9, with cover open 1,519 x 730 x 1,000 mm—Extension Vacuum-Feed Banner Sheet Tray Type S14, when attached to Vacuum-Feed LCIT RT5150 1,090 x 561 x 210 mm—Multi-Bypass Banner Sheet Tray Type S9, when attached to Multi-Bypass Tray BY5020 730 x 1,220 x 1,090 mm—Plockmatic LCT3500 2.0 1,113 x 730 x 1,490 mm—Finisher SR5110 1,334 x 730 x 1,622 mm—Finisher SR5110 with SR5000 Series Output Tray for Banner Sheet Type S6 1,876 x 730 x 1,617 mm—Finisher SR5110 with Extension Output Banner Sheet Tray Type S14 (installed on the upper tray) 1,926 x 730 x 1,617 mm—Finisher SR5110 with Extension Output Banner Sheet Tray Type S14 (installed on the lower tray) 1,113 x 730 x 1,490 mm—Booklet Finisher SR5120 1,334 x 730 x 1,622 mm—Booklet Finisher SR5120 with SR5000 Series Output Tray for Banner Sheet Type S6 1,876 x 730 x 1,617 mm—Booklet Finisher SR5120 with Extension Output Banner Sheet Tray Type S14 (installed on the upper tray) 1,926 x 730 x 1,617 mm—Booklet Finisher SR5120 with Extension Output Banner Sheet Tray Type S14 (installed on the lower tray) 1,115 x 591 x 555 mm—Trimmer Unit TR5050 740 x 730 x 1,350 mm—Cover Interposer CI5040 209 x 730 x 1,000 mm—Multi-Folding Unit FD5030 900 x 730 x 1,010 mm—High-Capacity Stacker SK5040 1,200 x 700 x 1,100 mm—Plockmatic High-Capacity Stacker HCI3500 900 x 680 x 1,060 mm—Plockmatic Multi-Purpose Stacker MPS1260 1,420 x 700 x 970 mm—Plockmatic PBM 5035S/PBM 5035, including stacker |

| Weight—mainframe | 1,100 kg or less |

| Weight—other | 230 kg or less—Vacuum-Feed LCIT RT5150 40 kg or less—Bridge Unit BU5010 20 kg or less—Multi-Bypass Tray BY5020 9 kg or less—Vacuum-Feed Banner Sheet Tray Type S9 23 kg or less—Extension Vacuum-Feed Banner Sheet Tray Type S14 9.5 kg or less—Multi-Bypass Banner Sheet Tray Type S9 250 kg—Plockmatic LCT3500 2.0 135 kg—Finisher SR5110 160 kg—Booklet Finisher SR5120 75 kg—Trimmer Unit TR5050 60 kg—Cover Interposer CI5040 45 kg or less—Multi-Folding Unit FD5030 131 kg or less—High-Capacity Stacker SK5040 135 kg or less—High-Capacity Stacker SK5040 with roll-away cart 250 kg—Plockmatic High-Capacity Stacker HCI3500 65 kg—Plockmatic Multi-Purpose Stacker MPS1260 lift unit 5 kg—Plockmatic Multi-Purpose Stacker MPS1260 docking unit |

| Minimum space requirements | 1,000 mm—front 1,000 mm—left 1,000 mm—right 800 mm—rear |

| Average monthly volume | 115 ppm—251,000 prints (A4), 159,000 prints (click); 135 ppm—460,000 prints (A4), 304,000 prints (click) |

| Max monthly volume | 1,000,000 prints |

| Machine life | 60,000,000 prints or 5 years, whichever comes first |

| Duty cycle | 115 ppm—2,250,000 prints; 135 ppm—2,600,000 prints |

| Colour ratio | 80% |

| Supply yields | 69,000 sheets—black 75,500 sheets—cyan 73,200 sheets—magenta 64,800 sheets—yellow230,000 sheets per waste toner bottle5,000 staples per Type X cartridge for Finisher SR5110 and Booklet Finisher SR5120—side staple 5,000 staples per Type U cartridge for Booklet Finisher SR5120—saddle stitch staple 5,000 staples per Type X refill cartridge for Finisher SR5110 and Booklet Finisher SR5120—side staple 5,000 staples per Type T refill cartridge for Booklet Finisher SR5120—saddle stitch stapleNote: Toner yields measured with the A4/8.75% coverage chart with 150 pages per job. Waste toner bottle yield measured with A4/8.75% coverage chart with 150 pages per job and 80% colour ratio |

| Standard input capacity (sheets) | 4,400 |

| Maximum input capacity (sheets) | 18,100 |

| Maximum output capacity (sheets) | 13,000 |

| Paper input configuration – standard | 2,200-sheet paper input tray x 2 |

| Paper input configuration – optional | 4,400-sheet Vacuum-Feed LCIT RT5150, Bridge Unit BU5010, 500-sheet Multi-Bypass Tray BY5020, 730-sheet Vacuum-Feed Banner Sheet Tray Type S9, 500-sheet Extension Vacuum-Feed Banner Sheet Tray Type S14, 500-sheet Multi-Bypass Banner Sheet Tray Type S9, 3,500-sheet Plockmatic LCT3500 |

| Paper output configuration – optional | Multi-Folding Unit FD5030, High-Capacity Stacker SK5040, 3,500-sheet Booklet Finisher SR5120, 4,500-sheet Finisher SR5110, Punch Unit PU5030, Trimmer Unit TR5050 for Booklet Finisher SR5120, 400-sheet Cover Interposer CI5040 |

| Paper output configuration – 3rd Party | GBC e-Wire, GBC StreamPunch Plus, Plockmatic HCI3500 High-Capacity Interposer, Plockmatic CT XL, Plockmatic PBM350e, Plockmatic MPS1260 Multi-Purpose Stacker, Plockmatic PBM5035S long sheet stitcher, Plockmatic 5035 long sheet stapler, Plockmatic SBT (Square Back Trimmer), Plockmatic RCT v.3.0 |

| Supported media | Standard paper input trays 1 and 2 Plain, Recycled, Prepunched Paper, Transparency, Tab Stock, Translucent Paper, Label Paper, Coated: High Gloss, Coated: Glossy, Coated: Matte, Envelope, Textured Paper, Tab Stock: Glossy, Tab Stock: Matte, Tab Stock: High Gloss, Envelope: Glossy, Envelope: Matte, Envelope: High Gloss, Carbonless PaperNote: Magnetic Paper, Metallic/Pearl Paper, Clear File Folder, and Synthetic Paper can be fed but quality is not guaranteed.Bypass tray Plain, Recycled, Prepunched Paper, Transparency, Tab Stock, Translucent Paper, EnvelopeNote: High Gloss, Coated: Glossy, Coated: Matte, Textured Paper, and Synthetic Paper can be fed but quality is not guaranteed.Optional Vacuum-Feed LCIT RT5150 Plain, Recycled, Prepunched Paper, Transparency, Tab Stock, Translucent Paper, Label Paper, Coated: High Gloss, Coated: Glossy, Coated: Matte, Envelope, Textured Paper, Tab Stock: Glossy, Tab Stock: Matte, Tab Stock: High Gloss, Envelope: Glossy, Envelope Matte, Envelope: High Gloss, Carbonless PaperNote: Magnetic Paper, Metallic/Pearl Paper, Clear File Folder, and Synthetic Paper can be fed but quality is not guaranteed.Optional banner sheet tray Plain, Recycled, Prepunched Paper, Coated: High Gloss, Coated: Glossy, Coated: Matte, Textured Paper, Carbonless PaperNote: Transparency, Translucent Paper, Label Paper, Magnetic Paper, Metallic/Pearl Paper, and Synthetic Paper can be fed but quality is not guaranteed. |

| Maximum paper size | 13″ x 19.2″ |

| Media weight (g/m2) | 40–470 |

| Limitless paper supply | Supported |

| Interfaces – standard | 10Base-T/100Base-Tx (Ethernet) 1000Base-T (Gigabit Ethernet)—for TotalFlow Advisor connection 2.5GBase-T—for Fiery controller connection SD slot x 2— for maintenance only USB 3.0 x 4, USB 2.0 x 2 |

| Interfaces – optional | With Color Controller N-50 10Base-T/100Base-Tx (Ethernet) 1000Base-T (Gigabit Ethernet) USB 2.0 x 4—rear USB 3.0 x 5—2 ports on the rear, 3 ports on the Fiery Quick Touch operation panelWith Color Controller N-70 10Base-T/100Base-Tx (Ethernet) 1000Base-T (Gigabit Ethernet) USB 3.0 x 7—rear USB 3.0 x 4 ports, x3 ports on the Fiery Quick Touch operation panel |

| Network protocols – standard | TCP/IP (IPv4, IPv6) |

| Network protocols – optional | With Color Controller N-50/N-70 Windows—TCP/IP Mac—TCP/IP, EtherTalk, Bonjour |

| Print speed colour | 115 ppm—A4 62 ppm—A3With optional Productivity Upgrade Unit Type S15 135 ppm—A4 75 ppm—A3 |

| Print speed black and white | 115 ppm—A4 62 ppm—A3With optional Productivity Upgrade Unit Type S15 135 ppm—A4 75 ppm—A3 |

| First print time | 115 ppm—24 seconds; 135 ppm—22 seconds |

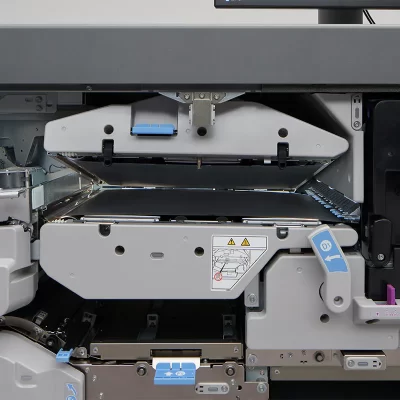

| Printing process | 4-drum dry electrostatic transfer system with internal transfer belt |

| Printing technology | Vertical-cavity surface-emitting laser (VCSEL) |

| Fusing | Oil-less belt-fusing method |

| Toner development | PXP-EQ chemical toner, polymerisation |

| Print resolution | 2,400 x 4,800 dpi Note: Engine print resolution is 1,200 x 4,800 dpi. |

| Duplex printing | Standard |

| Envelope printing | Supported |

| Maximum printable area | 326 x 1,255 mm |

| Optional printer controller | Color Controller N-50 and Color Controller N-70

System Base operating system CPU HDD 8 GB—N-50 Interfaces |

| Other print features | Optional Auto Color Diagnosis Unit and Image Quality Monitor |

| Other security features | The OneDFE controller security is based on the EFI Fiery security policy that is compliant with the FS500 Pro system. Contact your local sales company for more information. |

| Standard | @Remote TotalFlow Adviser |

| Optional | InfoPrint Manager Ricoh ProcessDirector TotalFlow Prep TotalFlow Production Manager TotalFlow BatchBuilder RICOH Supervisor TotalFlow Producer FusionPro VDP Creator FusionPro Expression Ricoh Auto Color Adjuster OL PlanetPress Connect Fiery Workflow Suite |

| Power source | 220–240 V, 50/60 Hz |

| Power consumption | 9,000 W or less—maximum power |

| Power consumption—options | 1,000 W or less—Vacuum-Feed LCIT RT5150 150 W or less—Finisher SR5110 150 W or less—Booklet Finisher SR5120 250 W or less, maximum—Trimmer Unit TR5050 75 W or less, average—Trimmer Unit TR5050 110 W excluding peak consumption—Cover Interposer CI5040 |

| Warm-up time | 540 seconds or less—mainframe |

| Sound power level | Mainframe 73.5 dB or less—standby 81.5 dB or less—operating |

| Reduction of environmentally sensitive materials | RoHS Less than 0.1 wt%—Lead, PVC, Hexavalent chromium, Cadmium, PBB/PBDE, DEHP, DBP, BBP, DIBP |

| Energy saving standards | Energy Star 3.2—with OneDFE controller |

| Safety standards | EN60950-1 IEC60950-1 KC 62368-1 CNS 15998-1 |

| Electromagnetic Compatibility (EMC) standards | EN55032 Class A EN61000-3-2 EN61000-3-3 EN55035 EN62311 KS C 9832 KS C 9835 KS C 9610-4-2 KS C 9610-4-3 CNS15936 Class A |

| Identification of plastic components | All plastic components that weigh more than 100 g are identified in accordance with ISO 11469 standards. |

| Laser standards | EN60825-1 IEC60825-1 |

Performance

Turbocharge your productivity

With the growing demand for shorter, more targeted runs, the RICOH Pro C9500 is the way forward. Built for high-volume shops, it exceeds expectations with remarkable results page after page. Keep work moving and push beyond with reliably that delivers one million pages per month. Gain the ability to replace paper and toner on-the-fly. Trained Customer Replaceable Units empower you to perform preventive maintenance without waiting on a technician.

Make every job more efficient

Work faster and with fewer errors with a new Fiery® N-70 Controller digital front-end solution, based on Fiery and Ricoh technology. Create an end-to-end, automated workflow to expedite production printing while achieving graphic arts quality. Amplify productivity and efficiency by processing larger, more complex files faster. RIP one file while processing another. Transition from job to job with ease. Manage offset and digital jobs in one workflow.

Robust paper capacity for long-run jobs

More operation, less interruption. Power through with a standard paper capacity of 4,400 sheets and a maximum paper capacity of 18,100 sheets. Turn to the Multi-Bypass Tray Unit to feed up to 500 sheets of specialty stocks, including an array of sizes up to 49″. The Vacuum Feed Large Capacity Input Trays ensure paper feeds continuously with a three-belt air-blasting tool that handles coated papers up to 173 lb. cover (470 gsm).

Our most intuitive control panel yet

Simplify operations with a full-view, 21″ color LCD touchscreen panel and transition between jobs effortlessly via fingertip control and animated guides. Intuitive visual guidance and programmable shortcut icons enable quick completion of both basic and advanced tasks. Essential information such as paper names in trays, jobs in the queue, and media settings are front and center. Get more done with remote access anywhere, anytime.

Services that deliver new pathways to success

With Ricoh your experience will be smooth from the start. Gain the support of an exceptional and knowledgeable professional services team who bring targeted expertise to every engagement. From operator training to finishing solutions, business development and G7 certification, tap into Ricoh as your single-source partner.

Intelligence now for a more sustainable tomorrow

Think green. We did on the RICOH Pro C9500 — an ENERGY STAR® certified device that’s EPEAT® Silver* rated. Meet your sustainability objectives and satisfy client requirements with an investment designed to help lower your environmental impact, while also reducing the total cost of ownership. Together with Ricoh, let’s continuously find new ways to promote energy efficiency and environmental sustainability. *EPEAT rating applies only within the U.S.

Finishing

Perfect Binders

Perfect Binder GB5010

Produce professionally trimmed, glue-bound, wrap around books of up to 200-sheets with covers and weights of up to 300 gsm. This inline option is ideal for catalogs, course books, small magazines, directories, and more.

Cover Interposers

Plockmatic High Capacity Interposer HCI3500

The Plockmatic High Capacity Interposer enables the automatic and inline insertion of a wide range of paper stocks up to 350 gsm within a single booklet. Vacuum feed technology ensures that thicker stocks are fed smoothly every time. Take advantage of two trays with 3,500-sheet total paper capacity and insert color covers and inserts in black and white runs.

Cover Interposer Tray CI5040

The Cover Interposer Tray allows pre-printed covers and inserts to be easily fed into the finishing workflow from two sources. This option eliminates the need for time-consuming offline manual insertion and reduces the wear and tear on originals.|Supports paper sizes up to 13″ × 19.2″ and media up to 130 lb. Cover (350 gsm).|Weight: 110 lbs. (50 kg)|W × D × H (inches): 13 × 28.7 × 50.8|W × D × H (mm): 330 × 729 × 1,290

Paper Handling

Multi Bypass Tray BY5020

Feeds up to 500 sheets of uncoated paper stocks for expanded system capacity and document output types. Support for stocks up to 13″ x 19.2″ in size and up to 80 lb. Cover (216 gsm) in weight.|Weight: 44 lbs. (20 kg)|W × D × H (inches): 27.2 × 22.1 × 8.3|W × D × H (mm): 691 × 561 × 211

Plockmatic LCT 3500

The Plockmatic LCT3500 Long Sheet Feeder can feed oversized sheets up to 27.5″ with weights up to 400 gsm. With the optional long sheet module, sheets up to 49.6″ can be fed into the system to produce long sheet applications such as trifold/gatefolds, landscape booklets, brochures and leaflets.

Stackers

High Capacity Stacker SK5040

For stacking up to 5,000 sheets of paper. Up to two stackers can be configured per engine.

Plockmatic MPS Oversize Sheet Stacker

Neatly stacks oversized output up to 49.6″, reducing labor and ensuring sheets stay flat before finishing.

Sheet Finishers

4,500 Sheet Finisher SR5110

The SR5110 offers multi-position staple finishing of up to 100 sheets for 8.5″ x 11″ sized media or 50 sheets for 11″ x 17″ sized media. The unit also offers stacking of up to 4,500 sheets (dual shift tray) with 4 staple options (top, bottom, 2 staples and top-slant). Two and three hole punch is available as an optional accessory.

Booklet Makers

Booklet Finisher SR5120

The SR5120 offers multi-position staple finishing of up to 100 sheets for 8.5″ x 11″ sized media or 50 sheets for 11″ x 17″ sized media. The unit also offers stacking of up to 3,500 sheets (dual shift tray) with 4 staple options (top, bottom, 2 staples and top-slant). Two and three hole punch is available as an optional accessory.

Plockmatic PBM 5035/5035 S

These production booklet maker accessories enable production of a wide variety of booklet formats, including landscape, in up to a 140-200 page range. Choose between staple or stitch versions for added versatility depending on anticipated volumes. A rich standard feature set including face trimming and square back spine formation, and other optional accessories, make this a true production workhouse.

Cutters/Trimmers

Trimmer Unit TR5050

Trims the “creep” side of a saddle-stitched booklet for professional looking booklets. Trims up to 30 sheets based on 20 lb. Bond, equivalent to an 120-page book.|Weight: 165.3 lbs. (75 kg)|Power Requirements: 120V, 50/60Hz, 15A|W × D × H (inches): 30.7 × 23.3 × 21.9|W × D × H (mm): 780 × 592 × 556

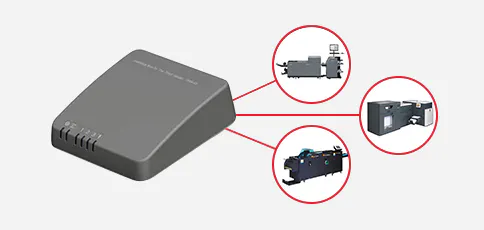

Other

RPIP Interface Port Type S3

Enable the inline connectivity of select third party finishing peripherals. This powerful solution greatly enhances your workflow, reduces labor time, and maximizes the value of traditional offline finishing equipment. Connect inline to the following finishing options: CP Bourg Booklet Maker BM-e, CP Bourg Watkiss PowerSquare™ 224, DSF-2000 Sheet Feeder and DBM-350 Booklet Maker

GBC StreamWire

A fully automated inline binding system for creating twin loop wire-bound booklets. StreamWire Spools are available in 3 Colors (Black, White and Silver) and in 5 different sizes.

basysPrint

basysPrint Cron

Cron Kodak

Kodak ECRM

ECRM HuQ

HuQ Heights

Heights G&J

G&J Digicut

Digicut ITOTEC

ITOTEC RICOH

RICOH Color Logic

Color Logic .

. akk

akk Labelmen

Labelmen intaGlios

intaGlios Canon

Canon Contex

Contex i2s

i2s