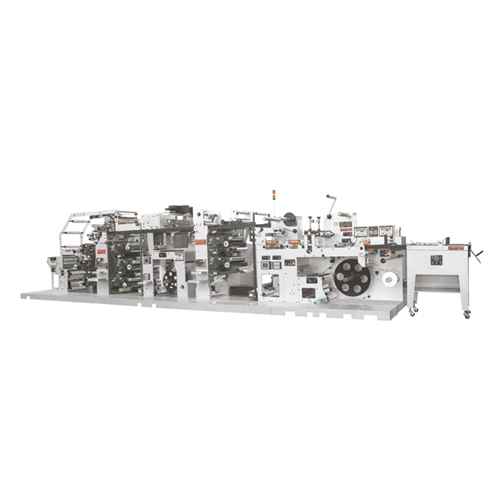

Labelmen PW-260-R8C

Full Rotary Letterpress

Quick change plate cylinder with gear, pre-registered impression drum for all printing stations etc, makes the fastest job set up speed for this type of machine in the world.

- Labels

- Flexible Packaging

- Laminated Tube

- IML, Lid, Box

FEATURES & BENEFITS

FEATURES & BENEFITS

PW-260-R8C

Full Rotary Letterpress

-

Quick job set up

-

Higher resolution by lower cost:

Use cold foil stamping glue applying by UV letterpress station can get better stamping effect (than flexo) also due to above reasons (e.g. thinner glue layer benefit for micro icon stamping etc).

-

Widest substrate types:

-

Maximized applications:

-

Various combinations:

Specifications

Specifications

| Specifications | PW-260-R8C | ||||||||||||||||

| Print station | 8 sets | ||||||||||||||||

| Flexo varnish print unit | 1 set | ||||||||||||||||

| Gearing | 1/8” cp | ||||||||||||||||

| Max. web width | 260 mm | ||||||||||||||||

| Max. printing width | 250 mm | ||||||||||||||||

| Unwind roll dia. Max. | 800 mm | ||||||||||||||||

| Rewind roll dia. Max. | 800 mm | ||||||||||||||||

| Print speed max. | 100 m/min | ||||||||||||||||

|

|

||||||||||||||||

|

|

||||||||||||||||

|

|

||||||||||||||||

| Machine Size (W*L*H) | 300*600*233.5 cm |

Applications

Applications

- Labels

- Flexible Packaging

- Laminated Tube

- IML, Lid, Box

Resources

basysPrint

basysPrint Cron

Cron Kodak

Kodak ECRM

ECRM HuQ

HuQ Heights

Heights G&J

G&J Digicut

Digicut ITOTEC

ITOTEC RICOH

RICOH Color Logic

Color Logic .

. akk

akk Labelmen

Labelmen intaGlios

intaGlios Canon

Canon Contex

Contex i2s

i2s