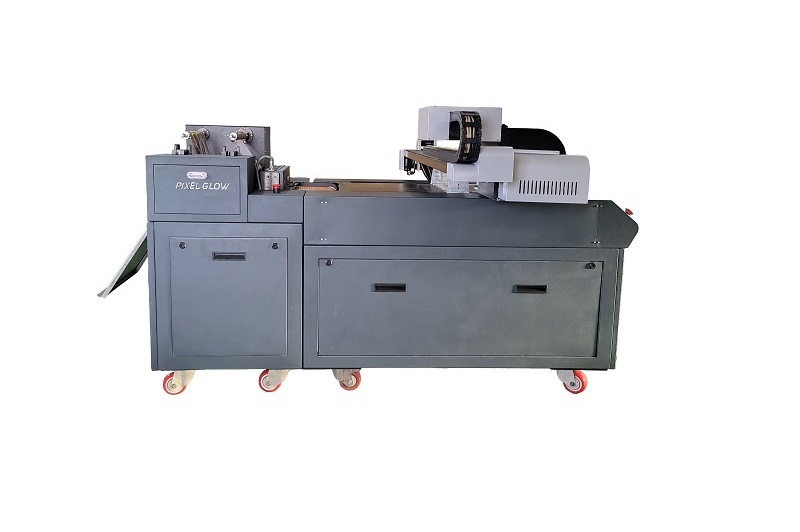

PixelGlow Radiant Pro

Print Enhancement Press Features (from Monotech Systems):

- Digital UV and foiling system

- Accurate and reliable at high-speed printing

- Efficient vacuum suction for flatbed operations

- Adjustable height system

- Variable drop technology

- Consistent print quality

- Pin mechanism for precise material positioning

- Adjustable UV LED power

FEATURES & BENEFITS

PixelGlow Our Print Enhancement Press with Spot UV and CMYK WV technology enables you to deliver brilliant, high-quality graphic communication products with tactile dimensions that stand out from competitors.

Adding special effects to digitally printed output makes print providers and the output they produce stand apart from the competition. Moving away from commodity print opportunities, print enhancement, and embellishment capabilities add value to print and demanded by the market too.

Lower-cost

It represents the print quality and the 3D effect comparable to expensive equipment previously released. You can achieve a high value at a reasonable initial cost.

Formats

Larger than A3 size(Up to 330 x 480 mm), material weight from 135gsm to 1000gsm, material thickness up to 3000 microns (3mm)

Sure quality

Add high impact to an ordinary printed output. Varnish thickness is up to 240 microns with special varnish ink.

Easy operation with optimization RIP software

Photo Print consists of a user-friendly and easy interface. Can use various print mode and easy settings.

SPECIFICATIONS

| Variants | 2006AF |

| Printing Technology | Drop on demand Inkjet-Multi Pass |

| Media Handling | Flatbed |

| Resolution | Up to 600 X 4800 DPI |

| Speed A3 Size (Per Hour – 1Pass) | With Registration 90+ Sheets Without Registration – 100 + |

| Variable Data | PDF, Optimized PDF*, TIFF |

| Supported Image Standards | Standard PDF |

| Substrates Weight | 170 – 500 GSM |

| Substrates Thickness | Up to 0.5mm / 500-micron |

| Registration Technology | CCD camera system with Automatic positioning |

| Communication Protocol | USB 3.0 |

| Substrates** | Digital, Offset, Laminated |

| Media Surface | 28 – 32 Dyne/cm – For Toner Sheets, ***28 – 40 Dyne/cm For Laminated |

| Substrates Loading Sizes | Minimum: L297 x W420 mm / 11.7 x 16.5 in Maximum: L355 x W508 mm / 14 x 20 in |

| Printing Image Size | Maximum: L340 x W490 mm / 13.4 x 19.3 in |

| UV Ink | Pixel Glossy UV Ink |

| Polymer Layer Thickness *** | Up to 320 Micron |

| Braille | Up to 230 Micron |

| Print Heads Maintenance | Manual Cleaning |

| Substrates Input System | Auto Feeding |

| Feeder Capacity | Up to 200 Sheets |

| Substrates Output System | Foldable Stacker |

| Foil Saving | Enabled |

| Foil Unit | Online Foil |

| Flat Foil | 10 Micron to 20 Micron |

| Foil Film Core Dia | 1 Inch |

| Foil Film Multi Roll | Multi Roll 4 Inch width |

| Cast & Cure (Optional) | Add-on Feature |

| Air Requirements | Air Flow: 5 CFM. Between 6-8 Bar – regulated/ 70liter Tank |

| RIP Software | X-Color / Photo Print V12 |

| Dimensions (L x H x W) | 144 x 52.6 x 82.6 inches |

| Operating Environment | Temperature: 20ºC to 27ºC |

| Electrical Requirements | Humidity: 40% to 80% relative humidity, non-condensing Single Phase + G + N Frequency: 50 Hz Current: Avg. 4 Amps in production Power consumption: Avg. 5.2KW in production Circuit Breaker: 16 Amps minimum |

| Weight | 1000 kg |

(*** On toner print – Height of varnish from 40μm onwards ) (* sheet 1pass with 27Micron / Per hour) (** Image to Image Position Tolerance ± 250μm)

basysPrint

basysPrint Cron

Cron Kodak

Kodak ECRM

ECRM HuQ

HuQ Heights

Heights G&J

G&J Digicut

Digicut ITOTEC

ITOTEC RICOH

RICOH Color Logic

Color Logic .

. akk

akk Labelmen

Labelmen intaGlios

intaGlios Canon

Canon Contex

Contex i2s

i2s