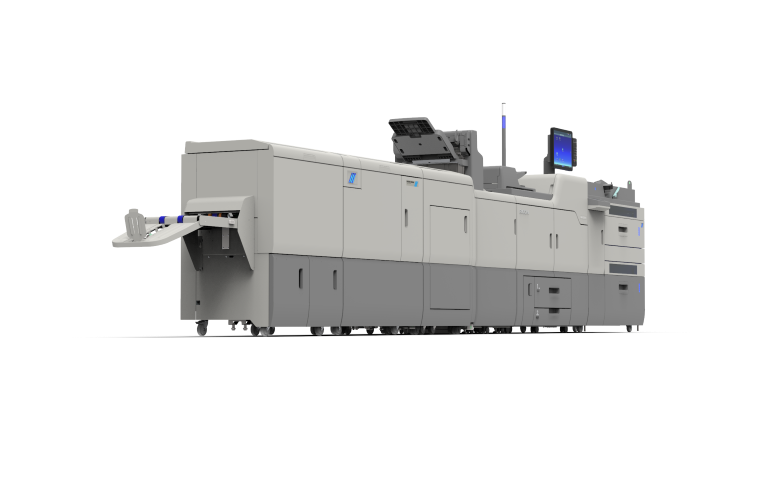

Major Paper Folder

The Morgana Major has been designed to offer a wide range of ‘big machine’ features within a compact and easy to operate design. Changing from one size to another, or for different folds, can be accomplished in seconds. The Morgana Major incorporates counting and batching, with perforating and scoring as standard in the UK and optional elsewhere.

A number of unique features have been developed to ensure that the Morgana Major can handle output from digital processes, as well as litho printing. Like all Morgana products, the Major offers unmatched performance and value.

The fold rollers are extremely durable and have the ability to handle a wide variety of stock without adjustment. Not affected by paper dust, their unique composite material will positively grip high gloss papers or work from digital print engines.

The Dial-a-Fold plate settings enable all adjustments to be made without removing the covers. An LED display, accurate to 0.1mm, shows the fold plate position and allows easy and accurate repeat job settings.

A larger sheet size of 365mm width and 648mm length makes the Morgana Major even more flexible, capable of producing 6pp A4 documents. The machine speed is fully adjustable from 4500 to 27,500 sheets per hour, giving the operator complete control over the production of a wide range of stocks.

Key Features

- Powerful suction feeder handles a wide range of paper weights

- Side lay alignment of the sheets, prior to folding

- Low pressure suction chamber to control curled paper before it enters the fold rollers

- Fully enclosed fold plates with ‘dial-a-fold’ and LED display, fitted with anti-static brushes, skew and micro adjustments

- Plug in perforating and scoring attachment

- Variable speed

- Tray to catch work when perforating or scoring

- Long delivery belt stacker

- Counting & batching

- Double sheet, anti jam detector

The many different printing processes available today can affect the characteristics of paper, creating curled or easily marked material. At the same time run lengths can vary from short to very long. The Morgana Major can handle both.

When buying any equipment, running, maintenance costs and residual values are an important considerations. The Morgana Major has been designed to fulfill these criteria.

An example are the fold rollers. These are extremely durable and are located in a single patented pull-out cassette. When replacement is needed, non-skilled personnel can achieve replacement in less than five minutes.

The Major fold-plate has ‘dial-a-fold’ which enables all adjustments to be made without removing the covers. An LED display accurate to 0.1mm shows the fold plate position and allows easy and accurate repeat job settings.

basysPrint

basysPrint Cron

Cron Kodak

Kodak ECRM

ECRM HuQ

HuQ Heights

Heights G&J

G&J Digicut

Digicut ITOTEC

ITOTEC RICOH

RICOH Color Logic

Color Logic .

. akk

akk Labelmen

Labelmen intaGlios

intaGlios Canon

Canon Contex

Contex i2s

i2s