KODAK FLEXCEL NX System

Unlock your NX advantage with brand new capabilities for flexible packaging!

Print whiter whites, cleaner colors and the smoothest transitions with brand new plate imaging innovations for the KODAK FLEXCEL NX System.

- Reduce impression with advanced surface patterns

- Use hybrid screening to print the smoothest fades

- Stabilize highlight dots with advanced “light valve” technology

FEATURES & BENEFITS

KODAK FLEXCEL NX System

Unlock your NX advantage with brand new capabilities for flexible packaging!

Print whiter whites, cleaner colors and the smoothest transitions with brand new plate imaging innovations for the KODAK FLEXCEL NX System. Expertly-engineered solutions build on the FLEXCEL NX System’s unmatched, proven capability to elevate shelf impact and control production costs.

PRINT BETTER WHITES

- Print smooth white layers without pinholes

- Maintain white opacity while reducing ink usage

- Avoid double hits, enabling increased productivity and reduced costs

IMPROVE PROCESS REPRODUCTION

- Reduce impression with advanced surface patterns

- Use hybrid screening to print the smoothest fades

- Stabilize highlight dots with advanced “light valve” technology

Do more with less

The KODAK FLEXCEL NX System is the original flat-top dot digital plate making system that is transforming flexographic printing. Shelf impact, production efficiency and sustainability … the FLEXCEL NX System delivers it all, with unique imaging technology and innovative materials that enable unprecedented image quality, stability and predictability in prepress and the pressroom. Kodak’s portfolio of FLEXCEL NX System solutions is ideal for virtually every flexo application including flexibles, labels and corrugated.

- Print smoother, higher-density solids without laying down more ink

- Print with higher line screens

- Print high-density white in a single pass

- Reduce the number of colors per job without sacrificing print quality

- Reduce press downtime and run presses faster

- Reduce makeready waste and ink consumption

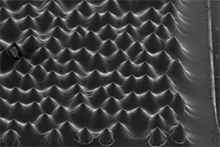

Flat top dots

The foundation for stable, predictable print

The FLEXCEL NX System’s groundbreaking flat top dot structure solves a problem inherent with traditional digital flexo platemaking technology, where oxygen inhibition during UV exposure results in bullet-shaped dots that are prone to surface wear and result in unpredictable inking and printing. The FLEXCEL NX System’s unique technology eliminates all oxygen during UV exposure to produce full amplitude flat top dots with sturdy bases and strong shoulders across the entire tonal range. The result is a printing form that is consistent, repeatable, resistant to changes in impression and wear from substrate or cleanin

| TRADITIONAL LAMS DOT | FLEXCEL NX SYSTEM DOT | FLAT TOP DOTS |

|

|

|

|

|

|

| PREDICTABILITY | SUPERIOR INK TRANSFER | |

|

|

|

|

Improved densities with micro-surface texturization

|

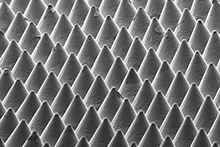

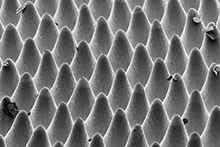

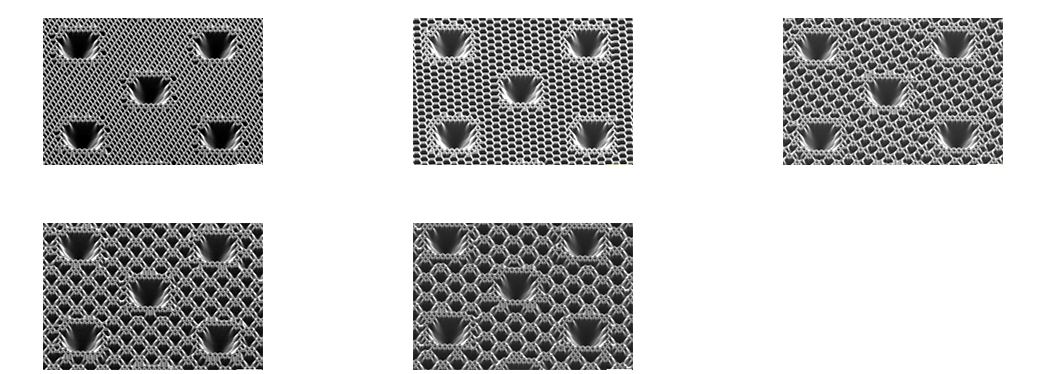

DIGICAP NX Patterning

A breakthrough ink transfer solution

KODAK DIGICAP NX Patterning is a software-based feature for the KODAK FLEXCEL NX System that enables a major step forward in ink transfer efficiency, through the application of a micro surface texturization pattern to the surface of all plate elements. Print applications that traditionally struggle with efficient ink transfer can now enjoy higher print densities, smooth solid area ink coverage and expanded color gamut with process printing. It is a development that allows flexography to truly compete on a quality level with roto-gravure for flexible packaging. DIGICAP NX Patterning helps you:

- Print smooth, solid area ink coverage

- Reduce patterns in solids and halo artifacts around reverses

- Increase solid ink density

- Reduce dot gain, especially in shadows

- Expand color gamut with process printing

NEW! advanced screen set expands capabilities Following two years of internal development, Kodak is introducing a select set of advanced patterns linked to anilox volume for maximum flexibility. This new pattern set uses expertly-engineered plate surface texturization technology to improve ink laydown in a wide variety of high-anilox applications including printing of white, spot colors, metallics and coatings. Applying advanced patterns to process reproduction also yields compelling benefits. ADVANCED SURFACE TEXTURIZATION PATTERNS

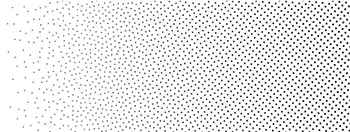

Hybrid Screening

Enable smoothest transitions

Innovative KODAK MAXTONE SX Screening, delivered in KODAK PRINERGY Workflow, is a hybrid AM screening solution that smooths the transition from highlights to midtones, effectively reducing the flexo break effect that can be seen in blends and vignettes. It allows the operator to set a minimum dot size in order to prevent the formation of dots that are too small for the flexographic process, and uses an FM-like screening technique to selectively remove dots, improving both highlight and shadow reproduction.

- Excellent control over highlights and shadows

- Minimize highlight gain and graininess

- 6 minimum dot choices: from 1×2 to 4×4 pixel dots

KODAK MAXTONE SX SCREENING SCALE

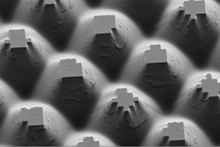

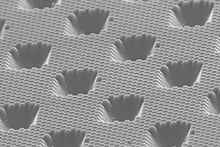

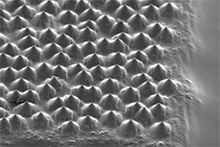

HYPERFLEX NX Imaging

Increase highlight dot stability

KODAK HYPERFLEX NX Resolution Enhancement Software represents a brand new generation of Kodak’s patented ‘light valve’ technology that has been optimized for the FLEXCEL NX System. This innovative software solution uses unique imaging capabilities to image 5×10 micron ‘light valves’ in automatically selected areas to raise the plate floor. The result? Increased highlight dot stability and consistency – especially in hybrid screens. HYPERFLEX NX Screening delivers:

- Optimum highlights at low impression

- Improved dot robustness

- Less impression needed

| WITHOUT HYPERFLEX NX IMAGING | WITH HYPERFLEX NX IMAGING |

|

|

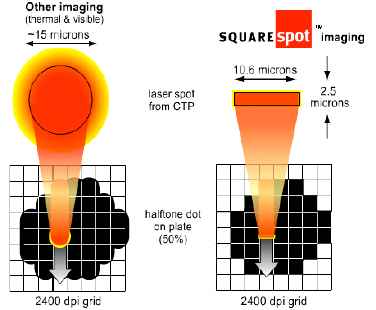

SQUARESPOT Imaging Technology

Award-winning, high-resolution thermal imaging technology

KODAK FLEXCEL NX Imagers use KODAK SQUARESPOT Imaging Technology, Kodak’s award-winning thermal imaging technology, to deliver a higher level of stability, accuracy and reliability in prepress and the pressroom. SQUARESPOT Technonlogy images at an effective resolution of 10,000 dpi to enable printing dots as small as 10 microns, and surface patterning down to 5 microns. Due to the unique nature of the imaging and reproduction process, files are ripped at just 2400 dpi, ensuring rapid file processing while delivering extraordinary results.

Specifications

Which configuration best meets your needs?

KODAK FLEXCEL NX Systems are available in four different configurations, and are suitable for virtually every flexo application.

Each system ships as a completely integrated turnkey solution:

- FLEXCEL NX Imager

- FLEXCEL NX Laminator

- TIFF Front End Software

- DIGICAP NX Patterning

- Densitometer

- FLEXCEL NX Thermal Imaging Layer and FLEXCEL NX Plates

- Media handling accessories, where appropriate.

| FLEXCEL NX Wide 5080 | FLEXCEL NX Wide | FLEXCEL NX Mid | FLEXCEL NX Narrow | |

|---|---|---|---|---|

| Imager dimensions (H x W x D) |

120 x 323 x 224 cm 47 x 127 x 88 in Loading table height: 84 cm / 33 in |

120 x 254 x 181 cm 47.2 x 100 x 71.3 in Loading table height: 83 cm / 33 in |

160 x 200 x 120 cm 63 x 79 x 48 in |

160 x 200 x 120 cm 63 x 79 x 48 in |

| Min. plate size | 610 x 762 mm 24 x 30 in |

610 x 762 mm 24 x 30 in |

610 x 762 mm 24 x 30 in |

610 x 762 mm 24 x 30 in |

| Max. plate size | 1270 x 2032 mm 50 x 80 in |

1067 x 1524 mm 42 x 60 in |

800 x 1067 mm 31.5 x 42 in |

|

| Resolution | 2400 dpi | 2400 dpi | 2400 dpi | 2400 dpi |

| Screening (flexo applications) |

|

|||

basysPrint

basysPrint Cron

Cron Kodak

Kodak ECRM

ECRM HuQ

HuQ Heights

Heights G&J

G&J Digicut

Digicut ITOTEC

ITOTEC RICOH

RICOH Color Logic

Color Logic .

. akk

akk Labelmen

Labelmen intaGlios

intaGlios Canon

Canon Contex

Contex i2s

i2s