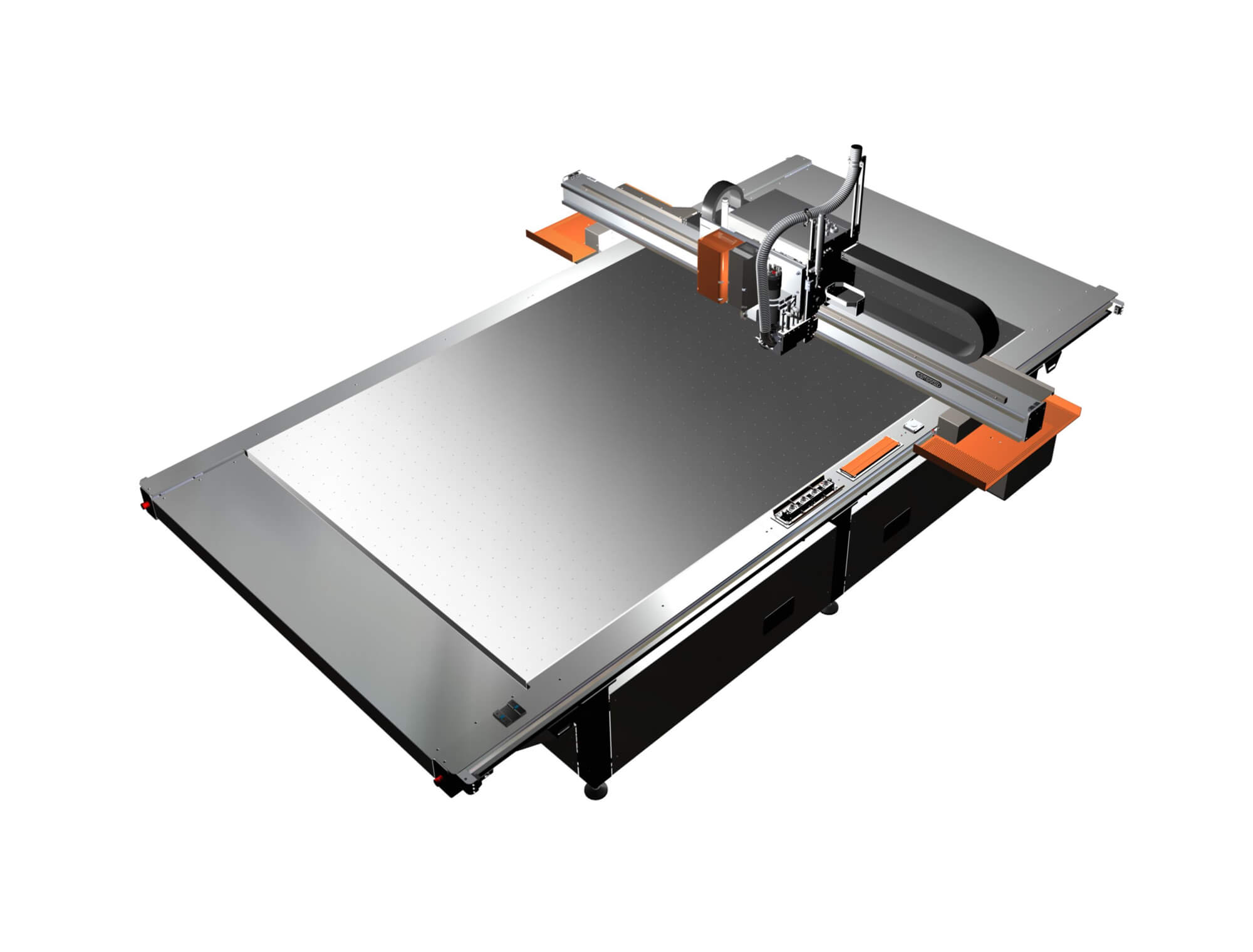

Comagrav Digi Corsa

The COMAGRAV DIGI CORSA is a versatile cutting and routing machine that can handle a wide range of materials, making it ideal for various industrial applications. It is equipped with an automatic tool changer, an unwinder, and can function as a table, providing a large-area cutting system suitable for industrial cutting, powerful milling, advertising production, packaging, sales support, exhibitions, and design work.

Key Features of COMAGRAV DIGI CORSA:

Automatic Tool Change: The COMAGRAV DIGI CORSA comes standard with an automatic tool changer on its multifunctional cutting and routing plotter. This feature allows for quick and seamless transitions between different tools and operations.

Powerful Spindle: The machine is equipped with a spindle that can reach up to 50,000 RPM, making it perfect for milling a variety of materials, including PMMA, Dibond, aluminum, PVC, and ABS.

Interchangeable Modules: The system’s interchangeable modules allow for a nearly limitless range of material processing capabilities. The machine can be easily upgraded with new modules as your business grows or as new materials and applications are developed.

Efficient Waste Management: The machine features a cyclone dust collector that efficiently removes waste from the cutting table, leaving almost no debris behind. Additionally, the dust collector includes an integrated spray cooling system for cutting aluminum and Dibond, ensuring clean cuts and extending the life of the cutter.

Quick Transition Between Operations: Switching from routing to cutting on the COMAGRAV DIGI CORSA takes only seconds, allowing for a flexible combination of operations.

Motorized Cutting Disc: The machine is equipped with a motorized cutting disc that effectively cuts through tarpaulins, banners, and fibrous materials, both woven and non-woven, enhancing its versatility across different applications.

Overall, the COMAGRAV DIGI CORSA is designed to grow with your business, adapting to new materials and evolving production needs. It offers powerful performance, flexibility, and efficiency in a single, comprehensive cutting and routing solution.

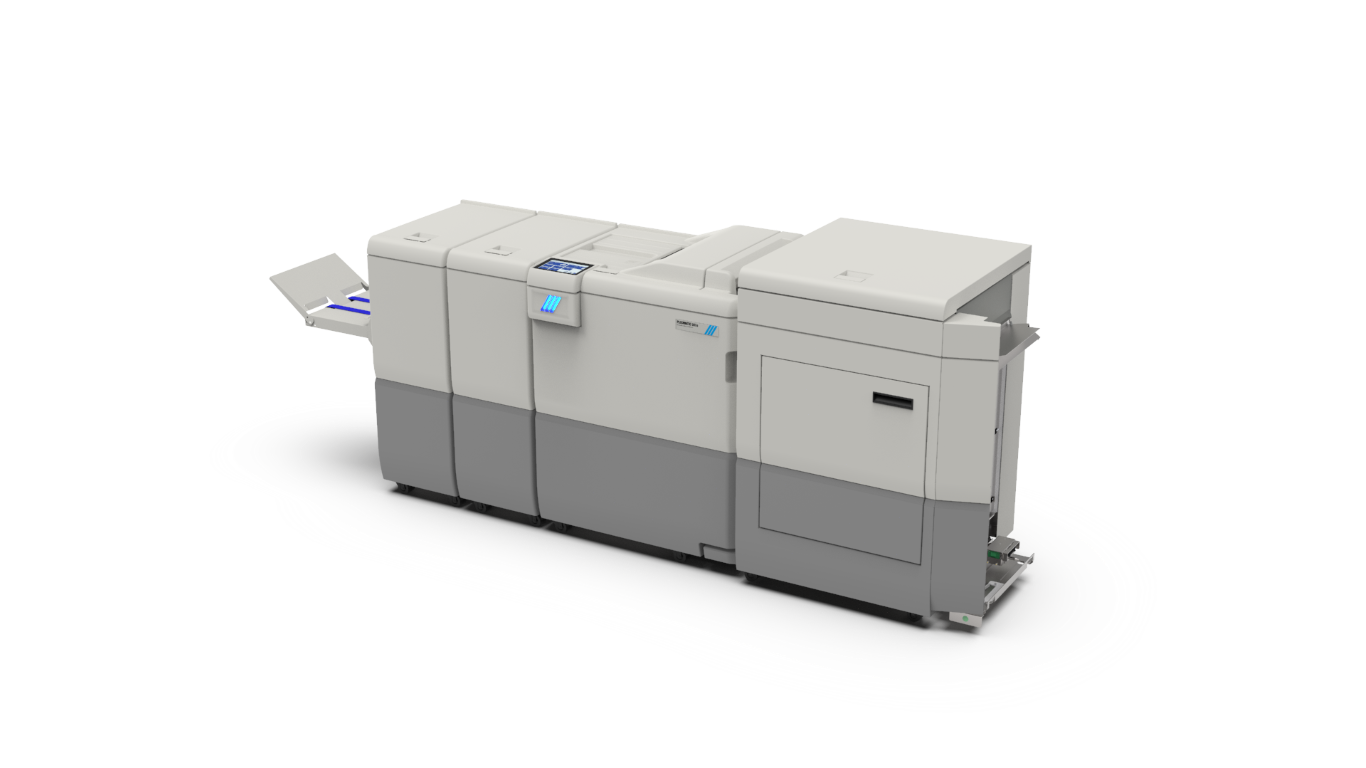

The COMAGRAV DIGI CORSA RC is a highly versatile cutting and routing plotter designed to handle a wide variety of materials, including acrylic, PMMA, aluminum, Dibond, corrugated cardboard, carton, sandwich boards, vinyl, textile, pre-pregs, banners, and more.

Wide ranging material handling with the COMAGRAV DIGI CORSA RC:

Wide Material Compatibility: The plotter is equipped to cut through a diverse range of materials, making it ideal for numerous industrial and commercial applications.

Material Unwinder with Integrated Camera System: The machine features a material unwinder that automatically feeds the material into the plotter. An integrated camera system reads QR codes from the material rolls, allowing the machine to cut file by file without the need for a machine operator. This automation significantly reduces labor costs, improves efficiency, and lowers maintenance requirements.

Advanced Software and Preset Libraries: The plotter comes with updated software and a library of presets, enabling it to perform precise cuts based on pre-programmed settings, further enhancing productivity and reducing the need for manual intervention.

Technical Specifications:

High-Performance AC Servomotors: The plotter is powered by AC servomotors paired with helical gearing, ensuring high accuracy in cutting operations.

Planetary Gearboxes: These are used in the drives, providing high cutting precision and allowing the plotter to achieve speeds of over 1 meter per second.

Robust Construction: Built with a rigid steel frame and a sturdy vacuum table, the COMAGRAV DIGI CORSA RC is designed for durability, with a lifespan that can last for decades.

High Precision and Speed: The combination of powerful motors, precise gearing, and advanced drive systems ensures exceptional cutting accuracy and fast operation, making this plotter a reliable choice for high-quality production needs.

Overall, the COMAGRAV DIGI CORSA RC plotter is a powerful and efficient solution for businesses looking to automate their cutting processes, handle a wide range of materials, and achieve high precision and speed in their production lines.

basysPrint

basysPrint Cron

Cron Kodak

Kodak ECRM

ECRM HuQ

HuQ Heights

Heights G&J

G&J Digicut

Digicut ITOTEC

ITOTEC RICOH

RICOH Color Logic

Color Logic .

. akk

akk Labelmen

Labelmen intaGlios

intaGlios Canon

Canon Contex

Contex i2s

i2s