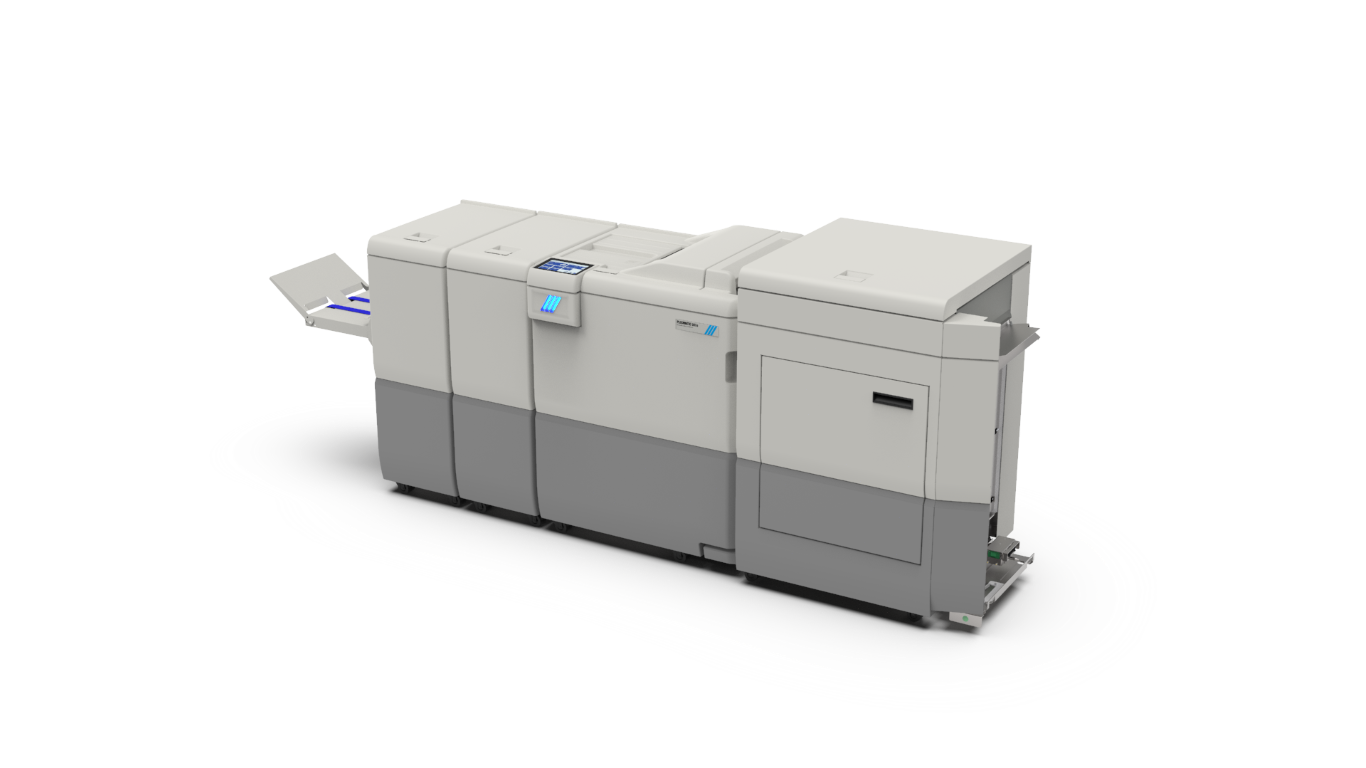

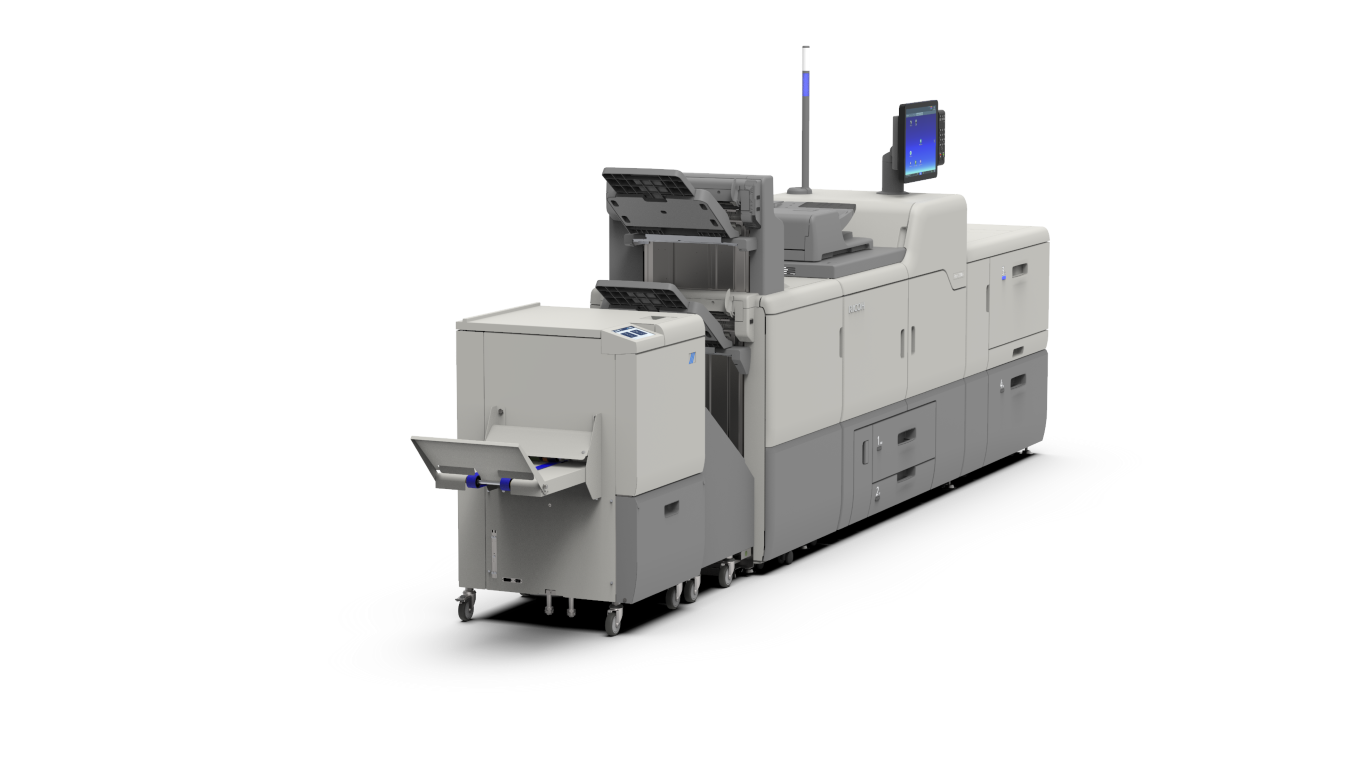

ColorCut FB9500 Pro-T digital die cutter/creaser

The ColorCut FB9500 Pro-T digital die cutter/creaser was developed with performance and flexibility in mind.

The digital die cutter/creaser is fully automated, ultra fast, with a faultless feeding system for reliable for unattended production to provide the perfect production and prototyping, finishing solution for your packaging, POS

The ‘No Wires’ working environment allows users to operate the cutter without being connected to a PC or to learn a new software program. This especially suits the production and manufacturing environments, where a fast turn around time is essential.

Key Features

- Digitally cut any shape at up to 1200mm/sec

- Digital process means no more costly dies

- QR code driven workflow – QR code/Job Library retrieves associated cut files – even for mixed job batch sessions

- Faultless feeding system – multiple feed procedures and customisable options for advanced sheet separation, enabling the feeding phase of production to be optimised to your needs

- Scans and cuts at the same time*!

- Concurrent task processing – *Scans and feeds subsequent sheets while cutting/creasing the previous, all in one smooth, synchronous operation

- Up to 20% faster output – typically, a verified, 20% faster than its nearest competitor

- Unique and Patented Rear Mark Scanning System – automatically scans the underside of the sheet, and cuts and creases from the unprinted top, enabling an optimised crease on certain media

- Superb 2.5kg crease with tangential wheel creasing tool

- SmartMark registration delivers incredible accuracy – enabled via included ColorCut Pro software

High-capacity and ultra-reliable feeding

The FB9500 Pro-T digital die cutter/creaser has been designed to provide unattended operation with particular attention paid to the feeding system to ensure class-leading performance for card, vinyl labels or even tricky laminated sheets. The auto feeder accepts up to 1,000 sheets, which automatically raises and lowers as required. To prevent sheets curling (as a result of a constant air flow to the sides), the machines use an automatic air blade that fires a blast of air momentarily into the front of the stack just as the advanced vacuum feed belt lowers to collect the top sheet. To further provide a reliable feed, the vacuum feed lifts the media carrying any sheets not pre-separated by the air blade past a pair of dexterous separation fingers which dislodges them. Finally, before advancing the sheet into the cutting engine, the vacuum feed shakes the sheet, to separate any additional sheets picked up by static cling, also the vacuum feed ‘jogs’ briefly against the rear paper stop, creating a natural curve that helps ensure even difficult media feeds faultlessly.

FB9500 Pro-T digital die cutter/creaser – Dual tool power with digital accuracy

The digital dual tool head, includes passive contour/drag cut, with active tangential creasing wheel and applies force, individually, for both the cutting and creasing tools.

This combination of tools provides a much wider media handling capability and more defined, smoother crease for thick card up to 450 micron. The individual tool actions are controlled via the included ColorCut Pro 5 Production Studio software.

In common with the entire ColorCut family, the tools can be set to apply exact amounts of pressure and speed (up to 1200mm/s), along with total control over the application of cut, crease, perforation or kiss-cut of vector artwork lines drawn in Adobe® Illustrator® or CorelDRAW®.

Tangential technology enables the FB9500 Pro-T to lift the tool up from the media, rotate it and lower it back onto the media.

Suitable for creasing wheels to enable more defined, smoother precise creases – particularly good for thicker media.

Ai control for automatic job retrieval and optimisation of production processes

The FB9500 Pro-T digital die cutter/creaser is built on the foundation of our next generation of Ai based ColorCut Pro software delivering new features, functionality, control and automation, redefining how automated

cutters can be used.

Customise all feeder and sheet transport parameters, including Belt speed and acceleration, ‘jog’ (page seperation) parameters, gravity restack function and more.

Easy and simple manual use or choose fully autonomous operation from the two 2 modes users can employ for cutting files.

In DIRECT mode: ColorCut Pro offers unparalleled flexibility and control over cutting and production from the connected PC. When creating jobs, the ColorCut Pro Client plugin applies an autoassigned QR code to each design, whilst auto-saving the cutting file (editable) to the ColorCut Pro Job Library.

In HELD mode: ColorCut Pro stores your job parameters, wrapping all the required settings into a custom held mode cut file, that can be transferred to a storage device on the cutter. This enables standalone operation, without the need for the main PC and can be cut at a later date by any operator.

The cutter checks the QR code on each sheet, retrieves the associated cut file and proceeds to cut and crease as required – even if the sheet is presented at 180°, reducing operator errors.

Ergonomic, immersive and highly productive

The new 7” immersive touch screen with extensive Info-Control system includes a live camera preview window delivering visual feedback of QR code and smart registration marks scanning.

Plus, feature rich options that provide an advanced level of control over the auto-feeder’s functionality. Useful for certain media that may require special handling or simply to optimise throughput of your chosen media.

The 7 inch immersive touch screen control panel can pivot to suit the angle desired by the operator.

A space-saving media catch tray slides away when not in use and the maneuverable stand ensures it is easily accommodated into any working environment.

ColorCut Label Media

Market leading features

- Digital label media to suit every application: pharmaceutical, beverage, personal care, postal, automotive, logistics and more

- Wide choice of paper and polyester stocks

- Standard sheet size SRA3 (320mm x 450mm)

- Designed to print smoothly. Dedicated adhesives withstand heat of laser printing ensuring sheet edges remain clean

- Optimal lay-flat when feeding through printer

- Designed for dry toner (laser) printers for premium print results

- Anti-static treatment on polyester media

- 100 sheet packs for efficient and safe media storage

*ColorCut Label Media is currently only available in UK & Europe

basysPrint

basysPrint Cron

Cron Kodak

Kodak ECRM

ECRM HuQ

HuQ Heights

Heights G&J

G&J Digicut

Digicut ITOTEC

ITOTEC RICOH

RICOH Color Logic

Color Logic .

. akk

akk Labelmen

Labelmen intaGlios

intaGlios Canon

Canon Contex

Contex i2s

i2s